|

| Click for larger view. |

Cartridge Heater Basics

Cartridge heaters are cylindrical in shape, consisting of an element made of resistance wire wound around a ceramic core. Within a metal sheath tube, the wound core is precisely centered and surrounded by granular magnesium oxide material. This isolates the resistance element from the tube electrically and provides a heat transfer medium to the sheath tube. At one end are electrical terminations. In order to enhance internal heat transfer and electrical insulation characteristics, higher performance, longer-lived cartridge heaters are swaged (a rotary hammer compacting process). Swaging compacts and densifies the granular insulating material, improving its thermal conductivity. Cartridge heaters are commonly used and are produced in a broad range of lengths, diameters, wattages, watt densities, lead agreements, and optional internal sensors.

Cartridge Heater Applications

|

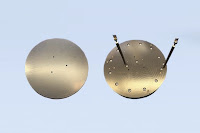

| Specialized Cartridge Heater (BCE) |

Cartridge heaters are capable of operating at elevated temperature as well as high watt density, but care must be taken to apply cartridge heaters at appropriate watt density and sheath temperature levels.

Temperature Capability

A maximum of 1600°F (870°C) sheath temperature is recommended.Watt Density Capability

A maximum of 400 W/in. and higher under special conditions. As a rule, cartridge heaters can operate at 1600°F at 40W/in.Heater Life

Operating at 1600°F internal temperature with modest cycling and with the proper hole fit, a properly designed and constructed cartridge heater will provide approximately a one-year life.Voltage

Usually 120/240V, with 480V and custom voltages requiring special design or sizing considerations.Thermal Response/Application

Cartridge heater's thermal response is dependent on conductive heat transfer in most applications. Optimum conduction requires close fit between the heater and the work to be heated. As heater looseness increases, watt density must be decreased accordingly, to prevent internal overheating. Watt densities of liquid-immersion cartridge heaters vary according to the liquid's viscosity and heat capacity. When heating liquids, care must be taken to prevent "film boiling" where vapor bubbles create a thermal insulating effect and raise the heaters internal temperatures.Heater Efficiency

Cartridge heaters are 100% efficient when immersed.For more information about electric heating elements, contact BCE by calling 510-274-1990 or by visiting https://bcemfg.com.