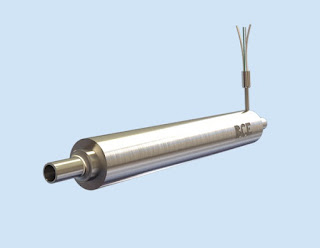

A semiconductor equipment company in the Atomic Layer Deposition (ALD) market approached BCE in need of a custom high temperature heater solution. Their application involved a thin-film deposition using a sequence of various chemical processes. Repeating these processes results in a thin film being slowly deposited.

A semiconductor equipment company in the Atomic Layer Deposition (ALD) market approached BCE in need of a custom high temperature heater solution. Their application involved a thin-film deposition using a sequence of various chemical processes. Repeating these processes results in a thin film being slowly deposited. SCOPE

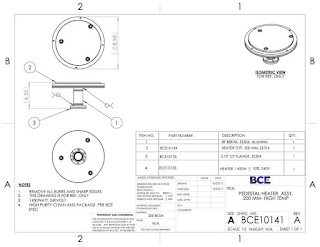

High Temperature Heater Chuck needed to satisfy the following:

- Temperature <700°C

- Internal element must be able to withstand higher than 700°C

- Thermal break between flange and base reducing heat transfer to flange area

- 316 Stainless steel base, sleeve, and flange must pass all required vacuum specifications

- 240Volt 1450Watt

- Built-in thermocouple type “K” inside internal element grounded with RF screening

OUTCOME

|

| Click for larger view. |

BCE produced a highly effective high temperature heater with exceptional uniformity. The design was able to compress the internal element enough to allow for optimal temperature transfer. The weld around the outside periphery of the base plate and the (3) lift–pin-hole-standoffs were essential in the design for vacuum integrity, ramp rate, and temperature stability.

For more information, contact BCE. Call them at 510-274-1990 or visit their web site at https://bcemfg.com.