|

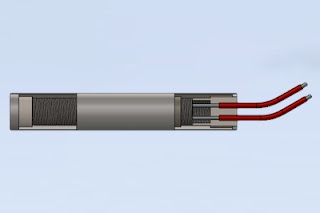

| Custom heater assembly that includes a sealed cartridge heater, thermowell, and thermocouples (multiple). |

What is a custom heater assembly?

In general terms, a custom heater assembly is a device that transforms electrical current to heat energy, is designed in a way that accommodates the needs of a unique heating requirement, and is used for the heating of gases, liquids, plastics, or metals.What is a thermowell?

A thermowell is machined metallic tube used to house and protect sensors or heating elements. Thermowells not only protect heaters and sensors from erosive or corrosive media, they also allow for easy removal and replacement without exposing the process media.What is a cartridge heater?

A cartridge heater is a cylindrically shaped electric heating element intended to be inserted in holes in metal platens or immersed in flowing media. The design incorporates a ceramic bobbin wound with nichrome resistance wire, carefully centered inside a metallic tube, and then backfilled with magnesium oxide (MgO), which provides electrical insulation. Cartridge heaters can be either swaged (compacted MgO) or un-swaged (loosely filled MgO). Swaging allows for maximum heat transfer to outside surfaces while keeping internal heater temperatures as low as possible, and preserving dielectric qualities.What is a sealed cartridge heater?

A sealed cartridge heater incorporates all of the characteristics of a standard cartridge heater but is additionally sealed with BCE’s proprietary epoxy seal making it vacuum compatible. The seal additionally elongates heater life, especially in high humidity and moisture environments.What electrical tests are performed on heaters?

Heaters undergo 3 main electrical tests: Resistance, MegOhm and Hipot.A resistance test is performed using a fluke meter to ensure that the heater is manufactured within the correct tolerances of the electrical specifications. Heater leads are connected directly to the fluke meter leads to perform the test.

A MegOhm or Insulation Resistance test is performed using a megohmmeter. As its name implies it tests for any breakdown in a heater’s insulating material. The test is performed by supplying low to medium voltage to the insulating material for a small period of time.

A Hipot test is also used to assess the dielectric strength of the heater’s insulating material. In addition to performing a Dielectric Withstand Test like the Megohm, it can also perform a Dielectric Breakdown Test. This means that the heater insulating material is shocked at very high voltages until failure is achieved. This is more commonly performed on samples as it destroys the heater.