An instructional blog about specialized electric heating elements and vacuum feedthroughs for the OEM, analytical, semiconductor, aerospace, pharmaceutical, chemical, water, environmental, food processing, and alternative energy markets. Please feel free to contact us at (510) 274-1990 with any questions. BCEmfg.com

Semiconductor Processing Chuck Heaters

Mini Clean Flow (MCF) Air Heater – Three Phase

- 250⁰C @ 120CFM using (2) units in a parallel flow pattern

- Stainless steel 304, all wetted parts

- Pressure tested to 90 PSI (or equivalent 5 x 10 ¯⁴ ATM, cc/sec or better)

- 3-phase with three heated zones

- (3) independent internal type “K” thermocouples for each zone

- 11KW (± 10%) , 240 Volt, 3-phase (or 1-phase optional)

- 36” Lead wires for each zone with 12” wire braid for strain relief

- 304SS CF 2.75 inlet and outlet flange

- Medium being heated: Air, ambient

- He Leak Tested = 5 x 10¯⁴ ATM, CC/sec or better

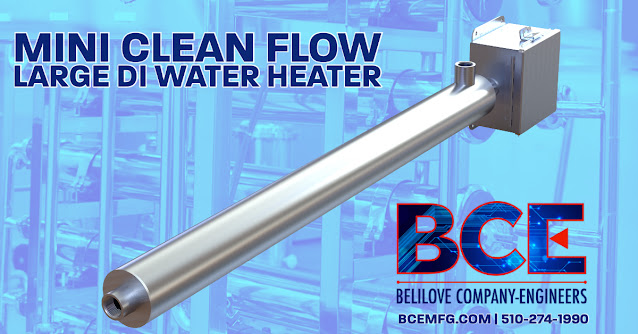

Mini Clean Flow (MCF) – Large DI Water Heater

- Temperature from 18ºC to 66ºC in 2 hours

- 316 Stainless Steel All wetted parts

- Pressure tested to 90 PSI

- NEMA 4 Housing

- RTD, 3-wire 100 ohm process sensor built-in near outlet

- An additional TC for bottom temperature read

- 16KW (± 10%) , 208 Volt, 3-phase

- Mounting threads on the bottom of the assembly

- Medium being heated: Deionized Water (DI Water)

- Recirculate at 3gpm

Vacuum Chamber Heater Platen 350mm

- Temperature 650⁰C-700⁰C

- 18” Long cold pin section with CF Vacuum Flange on the bottom

- Helium Leak rate of 1 x 10̄¯9 cc/sec He on CF Flange only

- 300mm x 350mm x 12.7mm thick for silicon and glass products

- Thermocouple built-in for over-temp protection or control

- 2,400 Watt (± 10%) , 240 Volt

- Mounting threads on the bottom of the assembly

- Material: 304 Stainless Steel

ALD Vacuum Chamber Pedestal Heater with Extended Sleeve

- Temperature 450⁰C

- 25” Long sleeve with 2.75 CF Flange on the bottom

- Body must pass Helium Leak rate of 1 x 10̄¯9 cc/sec He

- 6” overall diameter for 6” (152mm) wafers

- Top surface must have a flatness of ± .005”

- Thermocouple for additional temperature measurement

- 1,000 Watt (± 10%) , 120 Volt

- Material was 304 Stainless Steel

Mini Clean Flow Heater for Harsh Environments

- Temperature outlet needed to be 100⁰C

- Perpendicular configuration, with locking fittings

- Body must pass Helium Leak rate of 1 x 10-7 cc/sec He

- Pressure test of 50PSI

- Ability to place heater in a series flow configuration if necessary

- Thermocouple for additional temperature measurement

- 400 Watt, 120 Volt

- All wetted surfaces must be 304 or 316 Stainless Steel L (low carbon)

Experienced Electric Heating Element Designers Speed Development Time and Save Money in OEM Product Development

Technology advances rapidly, and findings in material science, medicine, pharmacology, biology, and semiconductors occur daily. These advancements in technology open the door for performance improvements leading to new treatments, medications, materials, and processes. Original equipment manufacturers (OEM's) of analytical, semiconductor, biomedical, life-science, and aerospace equipment continually design new equipment to apply and leverage these new discoveries.

Experienced custom electric heater designers provide many essential benefits throughout the product development cycle. For instance:

- Front-end, practical design review to optimize manufacturability.

- Timely prototype development.

- Strong alliances with vendors.

- Single source responsibility.

- Testing, calibration, and QC.

- Inventory management.

- Value-added assembly.

The heater manufacturer partner provides:

- Critical guidance in material selection.

- Power requirements under load.

- Temperature vs. time data.

- Watt density optimization.

- Packaging advice.

Their help provides high performance, precise fit, and extended heater life.

The pressure to produce new devices that offer greater efficiencies, compactness, and production is always present. Each item in the precedent design undergoes scrutiny and transitions to a contemporary fit, form, or function. New components are needed to meet the new design requirements. By choosing an experienced custom electric heating element design partner, the OEM gets the precision they need, plus scores of other benefits derived from the heater vendor's tacit knowledge and past experiences.