An instructional blog about specialized electric heating elements and vacuum feedthroughs for the OEM, analytical, semiconductor, aerospace, pharmaceutical, chemical, water, environmental, food processing, and alternative energy markets. Please feel free to contact us at (510) 274-1990 with any questions. BCEmfg.com

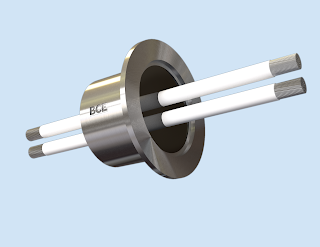

High Amperage Electrical Feedthrough

BACKGROUND

A customer involved in lithium ion research approached BCE in need of a high amperage feedthrough that also met their packaging (size) requirements.

While the customer had no problem finding high amperage feedthroughs, or feedthroughs that met their size requirement, they could not find an acceptable electrical feedthrough that satisfied both.

BCE is known for designing to customer specifications, allowing engineers the freedom to build their systems according to their plans, and not having to make design sacrifices because of hardware limitations. This application is an excellent example of BCE's capability.

OUTCOME

After a comprehensive application review with the customer, BCE went to work. Designs were completed in a few days and prototypes were completed in a few weeks. After preliminary tests and designs, a final prototype High Amperage Feedthrough was delivered for customer evaluation.

After thorough testing, the customer agreed that the application requirement was precisely met and the feedthrough functioned perfectly.

With the feedthrough now in production, all customer specified tests are performed prior to shipping and completed at BCE. Production and testing are controlled by a jointly developed standard operating procedure (SOP).

While this feedthrough was designed for a single, specific use, the underlying construction is designed to easily accommodate changes. Nearly every feature is customizable, including conductor type and gauge, flange type and size, component materials, and electrical rating.

The BCE High Amperage Feedthrough needed to satisfy these customer criteria:

A customer involved in lithium ion research approached BCE in need of a high amperage feedthrough that also met their packaging (size) requirements.

While the customer had no problem finding high amperage feedthroughs, or feedthroughs that met their size requirement, they could not find an acceptable electrical feedthrough that satisfied both.

BCE is known for designing to customer specifications, allowing engineers the freedom to build their systems according to their plans, and not having to make design sacrifices because of hardware limitations. This application is an excellent example of BCE's capability.

OUTCOME

After a comprehensive application review with the customer, BCE went to work. Designs were completed in a few days and prototypes were completed in a few weeks. After preliminary tests and designs, a final prototype High Amperage Feedthrough was delivered for customer evaluation.

After thorough testing, the customer agreed that the application requirement was precisely met and the feedthrough functioned perfectly.

With the feedthrough now in production, all customer specified tests are performed prior to shipping and completed at BCE. Production and testing are controlled by a jointly developed standard operating procedure (SOP).

While this feedthrough was designed for a single, specific use, the underlying construction is designed to easily accommodate changes. Nearly every feature is customizable, including conductor type and gauge, flange type and size, component materials, and electrical rating.

The BCE High Amperage Feedthrough needed to satisfy these customer criteria:

- 150 Amp 30 Volt

- Custom KF50 Flange

- Vacuum rating: 10-6 ATM-cc/s

- Feedthrough Seal Temp: -10 C to 60 C

- Able to withstand the weight of the heavy gauge wire

- ALL TESTS PERFORMED AT ROOM TEMPERATURE

Posted by

Belilove Company-Engineers

Labels:

electrical feedthrough,

high amperage feedthrough,

high current feedthrough,

vacuum feedthrough

Miniature Cartridge Heaters

Miniature cartridge heaters are roughly defined as electrical cartridge heaters 3" or shorter in length, having diameters of 1/8", 5/32", or 3/16", and providing high watt densities (although low to medium watt densities are available). Their exterior construction is usually 304 or 316 stainless steel, with internal nickel chromium (Nichrome) resistance wire. A variety of electrical lead wire configurations to meet the needs of the application are available. Because of their swaged (machine compressed) construction, miniature cartridge heaters provide a high level of shock and vibration resistance, as well as good dielectric strength.

Miniature cartridge heaters are roughly defined as electrical cartridge heaters 3" or shorter in length, having diameters of 1/8", 5/32", or 3/16", and providing high watt densities (although low to medium watt densities are available). Their exterior construction is usually 304 or 316 stainless steel, with internal nickel chromium (Nichrome) resistance wire. A variety of electrical lead wire configurations to meet the needs of the application are available. Because of their swaged (machine compressed) construction, miniature cartridge heaters provide a high level of shock and vibration resistance, as well as good dielectric strength.Miniature cartridge heaters are used to provide localized, concentrated heat to small component parts or in restricted work spaces. Dies and platens, as well as a variety of other types of OEM processing machinery, are efficiently heated by miniature cartridge heaters.

Typical OEM Uses for Miniature Cartridge Heaters

- Gas monitoring equipment / analyzers

- 3D printing machine

- Medical equipment and devices

- Ink printing and labeling machines

- Mass spectrometers

- Analytical process instrumentation

- Optical equipment

- Gas chromatography

For more information about miniature cartridge heaters, contact BCE.

https://bcemfg.com

510-274-1990

Custom Engineered Extrusion Die Heater Reduces Downtime, Increases Production

Extrusion plays an important role in the plastics industry. Unlike molding, extrusion is a continuous process that can be adapted to produce a wide range of finished or semi - finished products, including pipes, profiles, sheets, film and wire covering. Extrusion machines are fitted with a variety of dies.

Dies often require external heating to keep the plastic viscous. This is accomplished by using electric cartridge heaters inserted in holes in the die, or by other custom electric heating elements that are mounted to the die.

APPLICATION

A plastic extrusion customer approached BCE with a problematic heater that, upon its failure, would render the entire line out of commission. Not only did the failed heater stop production, but it also was difficult and time consuming to replace.

After reviewing the application, BCE engineers quickly determined the heater was designed as a consumable part with limited operational life, and little to no serviceability. BCE was going to have to design a replacement heater that would not only be a drop-in retrofit, but would be built to last and easy to replace if needed.

SCOPE

OUTCOME

After generating all the necessary drawings and 3D models, BCE’s engineers successfully designed and manufactured a circular custom heater assembly to replace the customer’s original part. Custom tubular heaters were embedded into a machined aluminum ring. The positioning of the heater terminals were key to the ease of replacement and had to be carefully engineered.

With this new, improved design, BCE was able to increase heater performance and efficiency, as well as guaranteeing temperature uniformity to within 2 °C around the periphery. Additionally, BCE modified the heater terminal electrical insulation to adequately support 240V (480V in series). Finally, the aluminum ring enclosure was designed to allow fast and easy replacement of the tubular heating elements, reducing down time and lost production.

For more information, contact:

BCE

https://bcemfg.com

510-274-1990

Dies often require external heating to keep the plastic viscous. This is accomplished by using electric cartridge heaters inserted in holes in the die, or by other custom electric heating elements that are mounted to the die.

APPLICATION

A plastic extrusion customer approached BCE with a problematic heater that, upon its failure, would render the entire line out of commission. Not only did the failed heater stop production, but it also was difficult and time consuming to replace.

After reviewing the application, BCE engineers quickly determined the heater was designed as a consumable part with limited operational life, and little to no serviceability. BCE was going to have to design a replacement heater that would not only be a drop-in retrofit, but would be built to last and easy to replace if needed.

SCOPE

- The heater needed to satisfy the following criteria:

- Continuous operating temperature of 200 °C.

- Minimal temperature deviation: ±2 °C.

- 10-32 tapped holes for custom terminal enclosure.

- Compatible with proprietary mounting fixture.

- Robust heater design to support long term continuous heating at 480 V in series .

- Heater plate designed for ease of access and serviceability.

OUTCOME

After generating all the necessary drawings and 3D models, BCE’s engineers successfully designed and manufactured a circular custom heater assembly to replace the customer’s original part. Custom tubular heaters were embedded into a machined aluminum ring. The positioning of the heater terminals were key to the ease of replacement and had to be carefully engineered.

With this new, improved design, BCE was able to increase heater performance and efficiency, as well as guaranteeing temperature uniformity to within 2 °C around the periphery. Additionally, BCE modified the heater terminal electrical insulation to adequately support 240V (480V in series). Finally, the aluminum ring enclosure was designed to allow fast and easy replacement of the tubular heating elements, reducing down time and lost production.

For more information, contact:

BCE

https://bcemfg.com

510-274-1990

Posted by

Belilove Company-Engineers

Subscribe to:

Posts (Atom)