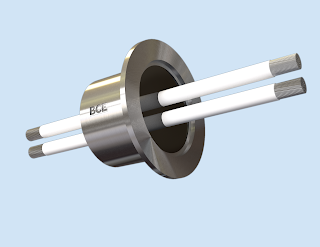

A customer involved in lithium ion research approached BCE in need of a high amperage feedthrough that also met their packaging (size) requirements.

While the customer had no problem finding high amperage feedthroughs, or feedthroughs that met their size requirement, they could not find an acceptable electrical feedthrough that satisfied both.

BCE is known for designing to customer specifications, allowing engineers the freedom to build their systems according to their plans, and not having to make design sacrifices because of hardware limitations. This application is an excellent example of BCE's capability.

OUTCOME

After a comprehensive application review with the customer, BCE went to work. Designs were completed in a few days and prototypes were completed in a few weeks. After preliminary tests and designs, a final prototype High Amperage Feedthrough was delivered for customer evaluation.

After thorough testing, the customer agreed that the application requirement was precisely met and the feedthrough functioned perfectly.

With the feedthrough now in production, all customer specified tests are performed prior to shipping and completed at BCE. Production and testing are controlled by a jointly developed standard operating procedure (SOP).

While this feedthrough was designed for a single, specific use, the underlying construction is designed to easily accommodate changes. Nearly every feature is customizable, including conductor type and gauge, flange type and size, component materials, and electrical rating.

The BCE High Amperage Feedthrough needed to satisfy these customer criteria:

- 150 Amp 30 Volt

- Custom KF50 Flange

- Vacuum rating: 10-6 ATM-cc/s

- Feedthrough Seal Temp: -10 C to 60 C

- Able to withstand the weight of the heavy gauge wire

- ALL TESTS PERFORMED AT ROOM TEMPERATURE