An instructional blog about specialized electric heating elements and vacuum feedthroughs for the OEM, analytical, semiconductor, aerospace, pharmaceutical, chemical, water, environmental, food processing, and alternative energy markets. Please feel free to contact us at (510) 274-1990 with any questions. BCEmfg.com

Take it All Through the Wall with Epoxy Vacuum Feedthroughs

|

| Glass-to-metal feedthrough |

Glass-to-metal and ceramic-to-metal seals, traditionally the preferred technology, are increasingly problematic - not because of their performance, but because they are constrained by size, geometry, flexibility, and electro-magnetic shielding options. Engineers worked within this reality simply because there were no viable alternatives. Fortunately though, new, advanced sealing epoxy compounds were developed that provided exciting opportunities for vacuum feedthrough manufacturers.

Faster, Less Expensive, More Customizable Feedthroughs

|

| Epoxy vacuum feedthrough. |

Today's epoxy vacuum feedthroughs provide the virtually the same performance as their glass and ceramic cousins in low to medium temperatures. Epoxy vacuum feedthroughs offer designers and engineers an excellent alternative in terms of customization and specialization. Shapes, angles and curves are not a problem. Virtually any kind of shielded wire or cable can be used. Custom epoxy vacuum feedthroughs can be quickly provided in very small quantities for prototyping and R&D. Modern epoxy feedthroughs maintain a vacuum up to 10-8 Torr, with temperatures up to 200°C continuous (300°C intermittent), and also meet NASA's outgassing requirement of <1.0% Total Mass Loss (TML). Liquid epoxy's ability to flow and fill spaces thoroughly provides it's advantage, and in most applications, an epoxy feedthrough can be used where a glass-to-metal or ceramic feedthrough is used - the only notable exceptions are in very high temperature applications or where organic compounds are not allowed.

Designers and engineers no longer have to think within the constrained world of glass-to-metal and ceramic-to-metal feedthroughs. Epoxy feedthroughs are a new, exciting player in town, and their lower cost, easy prototyping and more flexible design capability make them a very attractive alternative.

For more information, visit https://BCEmfg.com or call BCE at (510) 274-1990

Posted by

Belilove Company-Engineers

Custom Electric Heating Elements Provide OEM Designers Freedom and Flexibility

|

| Custom heater for vacuum applications with thermowell and multiple RTD sensors. |

Original equipment manufacturers (OEM's) of analytical, semiconductor, biomedical, life-science, and aerospace equipment continually design new equipment to apply and leverage these discoveries. Pressure to produce new machines offering greater efficiencies, compactness, and greater production is always present. Each item in the precedent design undergoes scrutiny and very often has be modified to a new fit, form, or function. New components are needed to meet the new design requirements.

The application of localized electric heating elements is one area that OEM design engineers find themselves navigating in unchartered waters. Very logically, they often attempt to use an off-the-shelf cartridge, silicone rubber, or mica heaters for their specialized heating requirement. Unfortunately this approach leads to compromises in layout, packaging, and performance. A much better alternative is considering a custom heating element, developed in consultation with an experienced custom heater manufacturer.

|

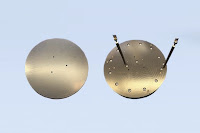

| Custom semiconductor wafer chuck heater. Highly uniform heat with no brazing or casting. |

- Front-end, practical design review to optimize manufacturability.

- Timely prototype development.

- Partnerships and alliances with platers, brazers, casters and heating element manufacturers.

- Single source responsibility.

- Testing, calibration, and QC.

- Inventory management.

- Value-added assembly.

|

| APCI Heater/Capillary Source Heater 400 deg. C, connector plug, and internal RTD sensor. |

By choosing a custom electric heating element design, the OEM gets exactly what they need in terms of form, fit, and function plus scores of other benefits derived from the heater vendor's tacit knowledge and past experiences.

Posted by

Belilove Company-Engineers

What is a Vacuum Feedthrough?

|

| Electrical Vacuum Feedthrough (Epoxy) |

Epoxy, glass or ceramic feedthroughs refer to the materials used to seal the conductor, tube, or fiber optic cable from the vacuum/process connection. Hermetic feedthrough refers to the device's nature of being airtight or vacuum tight, such as "hermetically sealed".

|

| Fiber Optic Vacuum Feedthrough |

Electrical feedthroughs use electrical conductors such as wires to deliver electricity inside the vacuum chamber.

Liquid and gas feedthroughs use metal tubes or fiber optic cables to introduce fluids or light beams.

|

| Liquid & Gas Vacuum Feedthrough |

Modern epoxy feedthroughs can now achieve vacuum up to 10-8 Torr, temperatures up to 200°C continuous (300°C intermittent), and meet NASA's outgassing requirement of <1.0% Total Mass Loss (TML).

For more information, contact BCE by visiting http://bcemfg.com or call (510) 274-1990.

Posted by

Belilove Company-Engineers

Labels:

ceramic feedthrough,

electrical feedthrough,

epoxy feedthrough and hermetic feedthrough,

glass feedthrough,

vacuum feedthrough

Subscribe to:

Posts (Atom)