|

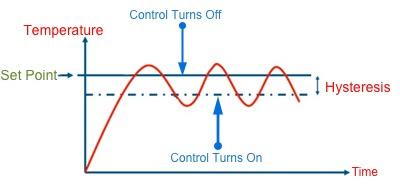

| Diagram of on / off control. |

A common method of temperature control is an on/off control system using comparison instructions in a PLC program where outputs are energized until the set point is reached.

The video below provides a temperature control example where the heater turns on when the temperature falls to or below 597 degrees, and turns off when the temperature reaches 603 degrees or more.

To control the circuit, S1 is programmed in the heater output circuit. Addressed to the move instruction is a thermocouple that provides an analog value to the temperature. The temperature is moved from the source to the destination when S1 is activated and is displayed on the LED panel.

Using the less than or equal to, and greater than or equal to, instructions addressed to the same integer file the source values have A and B are compared to control the heater. With source a less than source be at the less than equal to instruction, the low temp and heater outputs are enabled. The heater remains on as long as the low temp output is true and the high temp output is false.

As the temperature rises above source B at the less than or equal to instruction, low temp turns off and heating continues. Reaching 603 degrees or more, the high temp output is enabled, since source A is equal to source B of the greater than equal to instruction.

When the high temp output is true, the heater turns off and remains of until the temperature reaches 597 or lower. The cycle is repeated to maintain the average set point temperature at the other at 600 Fahrenheit.