An instructional blog about specialized electric heating elements and vacuum feedthroughs for the OEM, analytical, semiconductor, aerospace, pharmaceutical, chemical, water, environmental, food processing, and alternative energy markets. Please feel free to contact us at (510) 274-1990 with any questions. BCEmfg.com

Starwound Cable Heaters

Cable heaters are drawn, elongated, compacted heating elements with the electrical conductor protected inside a metallic sheath with magnesium oxide electrical insulation. Cable heaters are formed straight from round or square tubular stock. Once drawn and compacted, they are used as straight cable in some applications or assembled into various shapes, including star wound or spiral wound patterns. These configurations provide increased surface area, optimal heat transfer, compactness, and a fast heat up and cool down because of their small mass. Alloy 316 stainless steel cable heaters are commonly used in clean environments and where moisture or contaminants are present.

Starwound cable heaters provide optimal heat transfer of fluids (air, gases, liquids), yielding optimal heat distribution. The heater's flexibility allows for winding patterns that distribute power (wattage) precisely as required and generate high temperatures in tight areas. Starwound cable heaters placed inside pipes and ducts create a turbulent flow path, enhancing heat transfer and efficiency.

- Small diameter, low mass heater allows for fast heat up/cool down.

- Starwound element creates turbulent flow, resulting in more efficient heating.

- Sheathed stainless steel element for safely heating clean or impure gas, air, or liquid streams.

- Broad heater configuration is adaptable to any application.

HK 300mm Compressed Heater Chuck

BACKGROUND

To reduce the overall cost for an existing application, BCE developed a 300mm aluminum heater chuck that is un-brazed utilizing the compression of two plates with countersink set screws. The heater surface specs were 0.003” flatness at a 0.005” parallelism. Using a 208-volt power supply at 9.7ohm, start @ 25°C temperature and ramped from 100°C to 465°C in 23 minutes.

SCOPE

Aluminum Heater Chuck needed to satisfy the following:

- Achieve temperature up to 435°C @ +/- 2% or better

- Internal element must be able to withstand temperatures up to 600°C

- Anodized surface for electrical isolation

- 208 Volt, 9.7 Ohm, 4,460 Watt (+5% / - 10%)

- Thermocouple bore hole to be placed at the center (variable)

- 4 point temperature profile on the top surface of the heater

- Used an infrared sensor for each 4 point locations

- FINISH: Hard coat anodize per MIL-A-8625F, Type 3 Class1 Hard-coat thickness

OUTCOME

BCE produced a highly effective high 300mm heater with exceptional uniformity better than the proposed 435°C (+/-2%). After the initial ramp, the heater maintained 435°C (+/- 1%) as per the chart below (Temp profile #5).

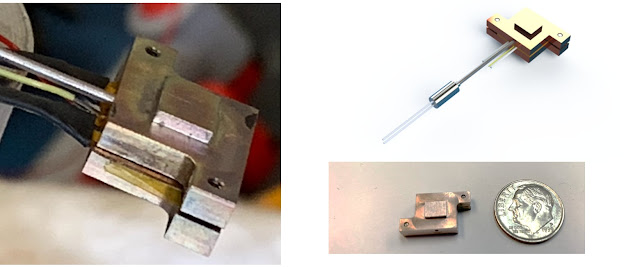

Molybdenum-Copper Stage Heater

BACKGROUND

A research and development company approached BCE wanting to heat a 1mm x 1mm x 0.5mm thick component. This was a very sensitive part that needed to be tested to a maximum exposure of 200°C continuous with very precise temperature uniformity for sampling purposes.

SCOPE

Molybdenum-Copper Stage Heater needed to satisfy the following:

- Temperature <201°C

- Internal element must be able to withstand temperature <210°C

- A cold section was not needed

- Molybdenum-Copper (Moly-Copper) base 65% Moly and 35% Copper

- 12Volt, 3Watt (Max)

- Two thermocouple type “K” external

- M1 threads

OUTCOME

BCE produced a highly effective assembly which reached the temperature of 200°C in under 1-Minute utilizing only 2.6 watts. Because of the low mass and high conductivity of the copper-moly base, reaching the target temperature and cooling down was highly efficient.

There were two thermocouples which were used to verify the test temperature. One was an exposed bare-bead TC 36 AWG, with the second TC being a 0.062ӯ probe style unit. The M1 threads were challenging, however our process was able to make this happen.

GET MORE INFORMATION ABOUT THE CUSTOM MOLYBDENUM-COPPER HEATER HERE

Call BCE today for more information.

510-274-1990

https://bcemfg.com

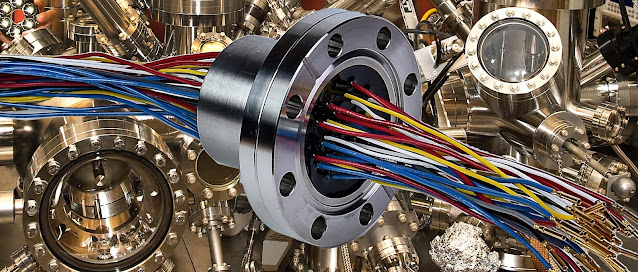

BCE Vacuum Feedthroughs Allow you to "Take It All Through the Wall"

The development capabilities for vacuum systems and components are continually refined by advances in analytical methods, medical science, and semiconductor manufacturing. The need for process monitoring and control is growing, and it is becoming increasingly difficult to get the necessary power and control signals into vacuum chambers. In order to pass electrical signals, light beams, or pure gases inside a vacuum chamber, devices referred to as vacuum feedthroughs are used.

Leakage into or through the vacuum feedthrough can not be tolerated as the vacuum seal is essential to preventing leakage and ensuring process integrity. Glass-to-metal and ceramic-to-metal seals, historically the favored technology, are increasingly troublesome - not because of their performance, but because they are limited by size, design, durability, and electro-magnetic shielding choices. Due to this fact, engineers worked with what was available because no suitable alternatives existed.

Fortunately, new, advanced sealing epoxy compounds were developed that provided exciting opportunities for vacuum feedthrough manufacturers. These new materials opened the door for a more efficient and flexible feedthrough design.

Today's epoxy vacuum feedthroughs have nearly the same application reach as their glass and ceramic cousins in low to medium temperatures. Epoxy vacuum feedthroughs provide an outstanding alternative in terms of customization and versatility for designers and engineers. Shapes, angles, and curves are not a concern. It is possible to use virtually any form of shielded wire or cable. Production in minimal amounts for prototyping and R&D, custom epoxy vacuum feedthroughs can be easily supplied. Modern epoxy feedthroughs sustain a vacuum of up to 10-8 Torr, with continuous temperatures of up to 200 ° C (intermittent 300 ° C), and therefore meet the outgassing criterion of NASA of < 1.0 percent Total Mass Loss (TML). Liquid epoxy's ability to flow and fill spaces thoroughly provides an important additional benefit. In most applications, epoxy feedthrough may be used where a glass-to-metal or ceramic feedthrough is used-the; only notable exceptions are in extremely high-temperature applications or where organic compounds are not authorized.

Within the restricted world of glass-to-metal and ceramic-to-metal feedthroughs, designers and engineers no longer have to wonder. Epoxy feedthroughs are a modern, exciting player in the game, making them a very enticing option with lower cost, fast prototyping, and more versatile design capability.

For more information about vacuum feedthroughs, contact BCE. Call them at 510-274-1990 or visit their website at https://bcemfg.com.

BCE Cartridge Heaters

BCE manufactures a wide range of cartridge heaters for a variety of industrial applications, and can provide you with heaters manufactured to your exact specifications. Cartridge heater size, sheath, leads, terminals, wattage and voltage can all be adapted to meet your exact needs.

Low to Medium Watt Density Cartridge Heaters

BCE precision cartridge heaters provided localized heat to restricted work areas requiring close thermal control. Dies, platens, and a variety of other types of processing equipment are efficiently heated and can be closely controlled. Part work temperatures of up to 1250ºF are obtained by a combination of heater location and proper wattage output. Basic heater designs are readily adaptable to a wide variety of special requirements, sizes, or ratings. Heating element wires are constructed just beneath outside surface for optimum heat transfer and minimum core temperature, resulting in faster part heating.

The maximum power densities for low to medium watt density cartridge heaters is computed at 60 watts per square inch of heated surface. With proper fit in a heat sink, long life can be expected. Consult BCE for higher watt density applications. Lower watt density will result in longer life. Standard voltages are either 120V or 240V. Other voltages are available.

High Watt Density Cartridge Heaters

The useful life of a Cartridge heating element is determined by how quickly the heat generated in the internal resistance wire can be dissipated to the outside sheath. BCE high watt density cartridge heaters are design and constructed in a way that accelerates the transfer of heat from the resistance wire to the sheath. This is accomplished by relocating the wire so that it is closer to the sheath; and swaging the outside diameter of the heater, thereby compressing the magnesium oxide filler so that it becomes an improved conductor of heat from the wire while maintaining its dielectric properties. By improving the heat transfer rate, it is possible to manufacture elements of higher densities because the differential between the wire temperature and the sheath temperature has been minimized.

Common applications for high watt density cartridge heaters are dies, heat sealing machines, hot melt adhesive equipment, plastic molding machines, platens, and shoe machinery.

Optimizing Performance and Operating Life of High Watt Density Cartridge Heaters

Cartridge Heater Fit

High watt density heaters require careful fit to insure optimum performance and long life. BCE recommends that installation holes not be drilled and reamed over .002” or larger than the nominal hole size required.

Cartridge Heater Cycling

Rapid cycling of heaters from very low to very high temperatures shortens their life considerably. It is recommended therefore, that care be taken to compute the correct wattage for any given installation. Optimum wattage should result in a 50/50 off/on cycle.

Location of temperature Sensor and Cartridge Heater

When thermostats are used, the sensing element ought not to be placed further than 1⁄2" away from the heater wherever possible.

For more information about cartridge heaters, call BCE at 510-274-1990 or visit their website at https://bcemfg.com.

Custom Electric Heating Elements for Aerospace, Satellites, and Space Exploration

BCE applies specialized know-how in top level design and production to supply electrical heating technologies for applications in the fields of aerospace, satellite communications and space exploration.

Providing electric heaters to the aerospace, satellite communications, and space exploration industries require pristine accuracy and conformance to exacting specifications. Heating elements must be designed to handle extremes in temperatures, shock and vibration, comply with exacting weight and size requirements, and be capable of operating in vacuum environments - all while still providing fail-proof performance.

BCE has decades of engineering and design experience in developing custom electrical heating elements for these industries. BCE's expertise has been called upon to solve many difficult application challenges unique to these applications, including viscosity control, condensation prevention, freeze protection, as well as air and gas heating.

BCE controls the entire manufacturing cycle including design, production and testing. Their understanding of electric heating technology, and the innovation accumulated along the way, is built upon decades of working closely with customers, meeting their critical requirements. Components and materials are carefully selected according to the customers’ exact specifications, many time turning out to be more than just the heating element itself. Products can be supplied as full assemblies complete with mechanical components, connectors, and sensors with batch sizes from a single piece to large volumes.

Contact BCE with any challenging electrical heating application in the aerospace, satellite communications, and space exploration field. You'll be glad you did.

BCE

https://bcemfg.com

510-274-1990

Types of Vacuum Feedthroughs

New Vacuum Feedthrough Product Designer from BCE

BCE, a California based manufacturer of high quality electric heating components and vacuum feedthroughs, is now offering a vacuum feedthrough product designing app on their website, bcemfg.com.

The app allows the visitor to select from an array of options and design their own vacuum feedthrough. Once the design is complete, the visitor can request pricing and delivery from BCE automatically though an integrated email messaging system. The visitor also receives a confirmation of their request.

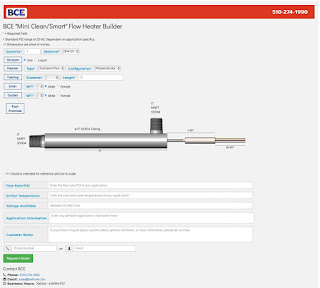

The vacuum feedthrough designer is the third in a series of online BCE product configuration tools. The three currently available are for cartridge heaters, BCE's Mini Clean Flow air and gas heaters, and now for vacuum feedthroughs.

You can check them out here - https://bcemfg.com/article_277_Product-Designer.cfm

BCE designs and manufactures custom electric heating thermal systems, electrical feedthroughs, pneumatic feedthroughs, and fiber optic feedthroughs. You can learn more about BCE at https://bcemfg.com, or if you have an immediate need, call them at 510-274-1990.

Improved Electric Heating Element Design Optimizes Rocket Engine Propellant Flow

You might think a rocket engine would give off enough heat to keep any part of the engine warm, but as it turns out, that's not the case. In many instances, the high flow of very cold propellants can cause obstructions in the propellant manifolds and valves. The need for localized heat becomes essential, and is normally provided by exterior, surface mounted, flexible resistive heating elements. The most common type of electric heater used in these applications are thin polyimide patches bonded directly to the valves and manifolds. While this approach may be convenient in terms of shape and mounting, that advantage is significantly reduced when you consider what you lose in heater efficiency and

heat uniformity.

BCE, a California based manufacturer of electric heating elements, has developed a better approach. Their BCE HEM Sealed Heater™ is designed to be inserted directly in the heated bodies, maximizing the heat transfer and heat uniformity. The HEM Sealed Heater™ is secured directly to components by the means of an integrated flange. In essence, the BCE HEM Sealed Heater™ incorporates both the cartridge heaters’ wire wound resistive element encased in a metal sheath and the vacuum compatibility of a feedthrough. Furthermore, the BCE proprietary epoxy seal allows the heater to pass strict electrical tests ensuring the purity of the dielectric materials and hence, preventing shorting.

BCE, a California based manufacturer of electric heating elements, has developed a better approach. Their BCE HEM Sealed Heater™ is designed to be inserted directly in the heated bodies, maximizing the heat transfer and heat uniformity. The HEM Sealed Heater™ is secured directly to components by the means of an integrated flange. In essence, the BCE HEM Sealed Heater™ incorporates both the cartridge heaters’ wire wound resistive element encased in a metal sheath and the vacuum compatibility of a feedthrough. Furthermore, the BCE proprietary epoxy seal allows the heater to pass strict electrical tests ensuring the purity of the dielectric materials and hence, preventing shorting.Learn more about the HEM Sealed Heater™here.

BCE

https://bcemfg.com

510-274-1990

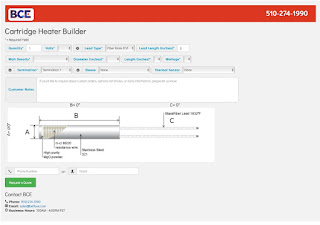

New! Product Builders for BCE Cartridge Heaters and Mini Clean Flow Heaters

|

| Cartridge Heater Product Builder (click for larger view) |

The user interface consists of an onscreen product drawing which is updated as each element of the design criteria is chosen. Once designed, it provides a finished drawing and allows the user to submit a pricing quotation request to BCE.

|

| Mini Clean Flow Heater Product Builder (click for larger view) |

For more information, contact BCE. Call them at 510-274-1990 or visit their website at https://bcemfg.com.

What Are Circulation Heaters?

Circulation heaters are the perfect solution for generating heat and enhancing normal immersion heaters performance. They are designed to heat pressurized circulating fluids and to provide effective, controlled heating to water, oil, steam and other gases. Circulation heaters are composed of all-in-one units with a heater mounted inside an insulated tank. They are made of a flanged or a screw plug immersion heater that is inserted into a pressure vessel or a pipe body. Heaters have inlet and outlet piping where the liquid or gas goes through the tank in order to reach the desired temperature.

Circulation heaters are the perfect solution for generating heat and enhancing normal immersion heaters performance. They are designed to heat pressurized circulating fluids and to provide effective, controlled heating to water, oil, steam and other gases. Circulation heaters are composed of all-in-one units with a heater mounted inside an insulated tank. They are made of a flanged or a screw plug immersion heater that is inserted into a pressure vessel or a pipe body. Heaters have inlet and outlet piping where the liquid or gas goes through the tank in order to reach the desired temperature.KEY FEATURES

- Standard sizes: 1.25” NPT screw plug size to 14” diameter

- Steel vessels fitted with 150 lb. flanges

- Thermal insulated vessels

- Custom unit sizes: up to 44” nominal pipe size

- Custom-designed to meet your specifications

- Special sizes, wattages, and materials are available upon request

- Units are available with larger vessels and heavier flanges

- Supplied with stainless steel parts and special design terminal boxes use in high temperature conditions

BENEFITS

- Easy to install

- Compact

- Clean

- Durable

- Highly energy efficient

- Provide fast response and even heat distribution

- Provide greater wattage in a smaller heater bundle

- Provide maximum dielectric strength

- Reduce heat loss from the vessel

- Protect and prevent thermal insulation

- Easy mounting support

- Suitable to general purpose terminal enclosures, weather or moisture resistant terminal enclosures, and unsafe or explosion proof locations

- Compatible with standard industry piping and safety standards

- Designed and built for safety

FACTORS

Please consider the following factors in order to select the proper circulation heater:

- Operating temperature

- Heating element watt density

- Sheath material (corrosive or non corrosive)

- Temperature of the corrodent

- Degree of aeration of exposed corrodent

- Velocity of the corrodent

REGISTRATION

Circulation heaters are sometimes considered as boilers or pressure vessels according to the:

- Heated fluid

- KW rating

- Size of vessel

- Operating pressure

- Outlet temperature

Where applicable, registration requirements are imposed by law and according to the installation location.

EXTRA FEATURES

- Available built-in high limit controls and thermostats

- Standard built-in thermostats: Single pole device limited to 240V up to 30 amps

- For heater voltage over 240V, or heater currents over 30 amps, or three-phase supply, the thermostat is used for pilot duty only and is not factory wired to the elements.

Please call BCE at 510-274-1990 if you have requirements for circulation heaters. You can also get additional information from the BCE website here.

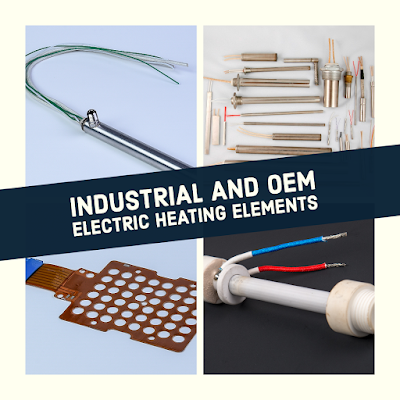

Industrial and OEM Electric Heating Elements

There are many places where electric heaters comes in touch with our lives each day. They are used to keep living spaces warm for human beings and animals (commonly referred to as "comfort heating"). Electric heating elements are found in common home appliances such as toasters, stoves, and hair dryers. But beyond the day-to-day consumer applications, electric heaters are also ubiquitous in industry. Industrial heating elements are critically important to many manufacturing processes, wether as an equipment component (OEM heaters), or directly used in the the processing of raw materials (industrial electric heaters).

In industry, electric heating elements are commonly used in the manufacture of electronics, semiconductors, medical devices, food equipment, plastics equipment, pharmaceuticals, glass, ceramics, primary metals, aerospace equipment, and HVAC equipment. While the industries that use electric heaters vary widely, the application of electric heaters narrows to the heating of flowing fluids (which include gases and air) or the heating of a solid metallic, or non-metallic, workpiece.

Types of Electric Heaters Used in Industry and Original Equipment Manufacturing

While the modes of transferring heat from on body to another will always be conduction, convection, or radiation, the mechanical and physical properties of industrial heaters change dramatically, depending on the media being heated, the physical and limitations of the application, and the application's temperature requirements. The following are the most common types of industrial and OEM heating elements used.