Electric heating elements are used to provide localized heat for people, animals, and equipment. Because electricity is widely available, it's a logical source of energy for the creation of heat. Electricity is converted to heat by the resistance to electrical current flow by a conductor. This process is known as Joule heating or Ohmic heating. The transfer of heat from heating element to the workpiece needing to be heated is done through conduction, convection, or radiation. Electric heat is simple, clean, and efficient. Unlike other forms of energy to create heat, such as fossil fuel or nuclear sources, there are no concerns with flammable fuels, radioactive materials, or harmful by-products.

There are many places where electric heaters comes in touch with our lives each day. They are used to keep living spaces warm for human beings and animals (commonly referred to as "comfort heating"). Electric heating elements are found in common home appliances such as toasters, stoves, and hair dryers. But beyond the day-to-day consumer applications, electric heaters are also ubiquitous in industry. Industrial heating elements are critically important to many manufacturing processes, wether as an equipment component (OEM heaters), or directly used in the the processing of raw materials (industrial electric heaters).

In industry, electric heating elements are commonly used in the manufacture of electronics, semiconductors, medical devices, food equipment, plastics equipment, pharmaceuticals, glass, ceramics, primary metals, aerospace equipment, and HVAC equipment. While the industries that use electric heaters vary widely, the application of electric heaters narrows to the heating of flowing fluids (which include gases and air) or the heating of a solid metallic, or non-metallic, workpiece.

Types of Electric Heaters Used in Industry and Original Equipment Manufacturing

While the modes of transferring heat from on body to another will always be conduction, convection, or radiation, the mechanical and physical properties of industrial heaters change dramatically, depending on the media being heated, the physical and limitations of the application, and the application's temperature requirements. The following are the most common types of industrial and OEM heating elements used.

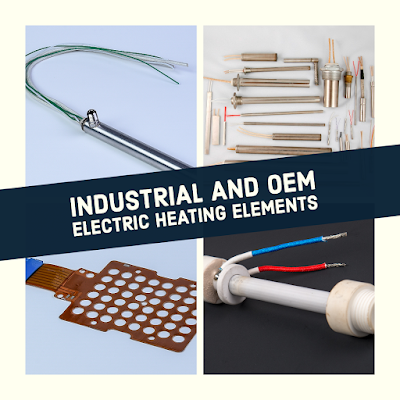

Tubular Heating Elements

Tubular elements are a common form of electric heater. Essentially a metal tube with resistance wire and electrical insulation inside, tubular elements can be configured into almost uncountable shapes and sizes.

Cartridge Heating Elements

Cartridge heaters provide localized heat to restricted work areas requiring close thermal control. Dies, platens and a variety of other types of processing equipment are efficiently heated.

Flexible Heating Elements

Flexible Heaters are made from a variety of materials such as Silicone rubber, Kapton, Mylar, or Neoprene and have etched foil or wirewound resistance elements. Fast responding with excellent heating profiles, these heaters solve many tough equipment heating challenges. Custom shapes and terminations are designed to suit. Rapid prototype service available.

Ceramic Heating Elements

Composed of high temperature materials such as alumina ceramic substrates. The metal heating resistance element is thickfilm technology or wire.

Thick Film Heating Elements

A process of depositing a resistor “trace” of tungsten paste on top of a ceramic part in a process very similar to screen printing. The deposition process allows for close control of thickness and width of the resistor, thus accurately controlling the conductor resistance, wattage, watt density, and uniformity of the heated part.