All of us at BCE wish our customers, vendors, and friends a very happy and prosperous 2018!

An instructional blog about specialized electric heating elements and vacuum feedthroughs for the OEM, analytical, semiconductor, aerospace, pharmaceutical, chemical, water, environmental, food processing, and alternative energy markets. Please feel free to contact us at (510) 274-1990 with any questions. BCEmfg.com

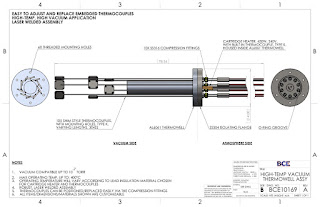

Electric Heating Element in Thermowell for Vacuum Applications, with Feedthrough and Multiple Thermocouple Sensors

|

| Click on image for larger view. |

The thermocouples can be easily mounted to any part in a vacuum chamber by the means of shims with mounting holes. Furthermore, they can be positioned with ease due to integrated compression fittings, which also allow for easy replacement of the thermocouples should the need arise.

A 304 Stainless Steel flange achieves a vacuum tight seal into any vacuum or degassing chamber port and there is virtually no outgassing, enhancing performance in high-vacuum environments.

Finally, a cartridge heater embedded inside an Aluminum 6061 thermowell allows for uniform and efficient heating of the chamber.

Scientists, researchers and engineers can all benefit from this high vacuum, barrier-breaking design.

For more information visit this link, or call BCE at (510) 274-1990.

Posted by

Belilove Company-Engineers

Labels:

electric heater,

thermowell,

vacuum,

vacuum feedthrough

Cartridge Heater Design

First, it's important to understand a very basic concept when applying electric heating elements. All electric heating elements need to move the heat away from the resistance wire into the surrounding media. This is done through conduction, convection, and radiation. Preventing resistance wires from getting too hot is the goal.

The difference comes down to internal design.

|

| Low watt density cartridge heater. |

|

| High watt density cartridge heater. |

High watt density cartridge heaters, capable of higher operating temperatures and long life include a different internal design, incorporating a swaging process and great care to resistance wire placement. High watt density heaters have very precisely wound nichrome resistance wire around the ceramic bobbin, and then, with exact centering and very tight tolerances, vibrate MgO into the metal tube surrounding the bobbin/wire core. Once the MgO is added, the heater goes through a swaging process that reduces the inner diameter of the metal tube. The result is compacted magnesium oxide with rock-like properties and much better thermal conduction from resistance wire to external heater sheath.

Both styles of cartridge heaters have their value and proper application. Using low watt density cartridge heaters on a simple applications like glue pots is fine, and will yield good life and performance. On the other hand, high temperature applications such as plastic injection mold machines require the higher performance and extended life that only a swaged heater will provide.

Contact BCE for more information on electric heating elements. Visit https://www.belilove.com or call (510) 274-1990.

Posted by

Belilove Company-Engineers

Aluminum Nitride Heating Elements

Aluminum nitride (AlN), a new generation of ceramic material, exhibits excellent performance for temperature, corrosion resistance, stability, high strength, and hardness. With the introduction of this new material to world of electric resistance heating element technology, AlN ceramic heaters are creating a good deal of excitement for equipment designers. AIN is opening new opportunities in power densities, space savings, and material compatibility.

Because they are capable of achieving up to 2000 watts per square inch, and operating temperatures of up to 1000 deg. C, AIN heaters show great promise for semiconductor processing applications such as crucible heating, fluid and gas handling and chemical vapor deposition. Able to operate in atmospheric and vacuum environments with excellent thermal efficiency, AIN heaters can also be designed with a multi-layer construction.

AIN heaters are ideal for applications that require very high watt density, and are an attractive alternative to traditional metal sheathed heaters that have limitations in thermal performance, material compatibility, fatigue, outgassing and thermal lag. AIN heaters are also resistant to most chemicals, acids and alkaline solutions.

These compact, robust heaters are an ideal solution for demanding thermal applications. Ceramic heaters can be custom designed to optimize thermal performance for the applications and RTD sensors can be deposited right on the ceramic heater itself for optimum control.

The most promising opportunities for AIN heaters exist in analytical instruments, semiconductor and medical equipment where high power densities, fast response, low mass, and corrosion resistance are often needed.

For more information on aluminum nitride heaters, or any custom thermal solution, contact BCE at https://www.belilove.com or call (510) 274-1990.

Because they are capable of achieving up to 2000 watts per square inch, and operating temperatures of up to 1000 deg. C, AIN heaters show great promise for semiconductor processing applications such as crucible heating, fluid and gas handling and chemical vapor deposition. Able to operate in atmospheric and vacuum environments with excellent thermal efficiency, AIN heaters can also be designed with a multi-layer construction.

AIN heaters are ideal for applications that require very high watt density, and are an attractive alternative to traditional metal sheathed heaters that have limitations in thermal performance, material compatibility, fatigue, outgassing and thermal lag. AIN heaters are also resistant to most chemicals, acids and alkaline solutions.

These compact, robust heaters are an ideal solution for demanding thermal applications. Ceramic heaters can be custom designed to optimize thermal performance for the applications and RTD sensors can be deposited right on the ceramic heater itself for optimum control.

The most promising opportunities for AIN heaters exist in analytical instruments, semiconductor and medical equipment where high power densities, fast response, low mass, and corrosion resistance are often needed.

For more information on aluminum nitride heaters, or any custom thermal solution, contact BCE at https://www.belilove.com or call (510) 274-1990.

Electric Heating Element Application and Engineering Reference Guide

Applying and specifying electric heating elements can be complicated. Make the job easier by downloading our handy reference guide (courtesy of Backer Hotwatt). The reference guide includes many of the electrical, mechanical, and physical properties you'll need to know when calculating wattage, evaluating maximum watt densities, and selecting proper heater placement.

Applying and specifying electric heating elements can be complicated. Make the job easier by downloading our handy reference guide (courtesy of Backer Hotwatt). The reference guide includes many of the electrical, mechanical, and physical properties you'll need to know when calculating wattage, evaluating maximum watt densities, and selecting proper heater placement.CONTENTS

- Wattage Calculation Formulas and Examples

- Properties of Metals

- Properties of Non-Metallic Solids

- Properties of Liquids and Gases

- Suggested Watt Densities

- Estimates of Wattage Required

- GuideforHeatLosses

- Suggested Sheath Materials

- Thermal Systems

- Installation

- Ohms Law

- Wiring Diagrams

- Mathematical Conversions

- Wire, Cable and Current Capacities

- Wire Gage Data

- Pipe Sizes and Threads

- Resistance Wire - Current vs. Temperature

Contact BCE for any electric heating element or thermal system requirement. Visit them at https://www.belilove.com or call (510) 274-1990.

Posted by

Belilove Company-Engineers

Labels:

Air Process Heaters. Cartridge Heaters,

Band Heaters,

Circulation Heaters,

electric heater,

Flexible Heaters,

Glasrope Heaters,

heating element,

Hotwatt,

Immersion Heaters,

Strip Heaters

Subscribe to:

Posts (Atom)