21060 Corsair Blvd.

Hayward, CA 94545

510-274-1990

https://bcemfg.com

An instructional blog about specialized electric heating elements and vacuum feedthroughs for the OEM, analytical, semiconductor, aerospace, pharmaceutical, chemical, water, environmental, food processing, and alternative energy markets. Please feel free to contact us at (510) 274-1990 with any questions. BCEmfg.com

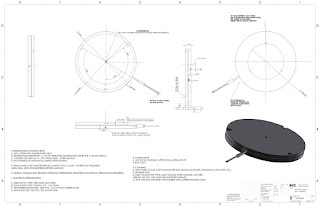

With the existing chip shortage, an atomic layer deposition (ALD) application up to 360⁰C was the focus of the latest BCE Vacuum Heater Chuck. A compressed assembly was used with many vacuum holes and grooves in the bottom plate to allow the gases to escape during pump down of the vacuum chamber. No surface anodizing was required.

BCE produced a highly effective vacuum heater which reached an atmospheric temperature of 360°C in under 30 minutes. The reduced mass on the bottom plate provided proper gas elimination with a quicker initial ramp time. Due to this decreased ramp time in atmosphere, a reduced wattage may be an option for the next iteration of the 450mm Vacuum Heater Chuck.

In a recent test the BCE Copper Molybdenum (CuMo) Vacuum Heater Chuck performed admirably past its stated rating of 850º C up to 900º C during ramp-up and heater stabilization.

The BCE Copper Molybdenum capability of 850º C clearly outperforms aluminum heater chucks temperature threshold of 450º C by a large margin, and also provides the benefit of more uniform heat distribution.

For more information contact BCE. Call them at 510-274-1990 or visit this web page.

BACKGROUND

An ALD chamber needed to be upgraded to a higher temperature platen, beyond the limits of aluminum. The application involved reducing the cost of a replacement vacuum heater while keeping the heat transfer and uniformity the same or better in vacuum. Vacuum integrity was crucial to the success of the project since it needed to comply with the existing vacuum heater chuck being replaced.

SCOPE

OUTCOME

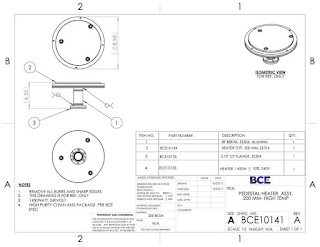

To reduce the overall cost for an existing application, BCE developed a 300mm aluminum heater chuck that is un-brazed utilizing the compression of two plates with countersink set screws. The heater surface specs were 0.003” flatness at a 0.005” parallelism. Using a 208-volt power supply at 9.7ohm, start @ 25°C temperature and ramped from 100°C to 465°C in 23 minutes.

SCOPE

Aluminum Heater Chuck needed to satisfy the following:

OUTCOME

BCE produced a highly effective high 300mm heater with exceptional uniformity better than the proposed 435°C (+/-2%). After the initial ramp, the heater maintained 435°C (+/- 1%) as per the chart below (Temp profile #5).

A semiconductor equipment company in the Atomic Layer Deposition (ALD) market approached BCE in need of a custom high temperature heater solution. Their application involved a thin-film deposition using a sequence of various chemical processes. Repeating these processes results in a thin film being slowly deposited.

A semiconductor equipment company in the Atomic Layer Deposition (ALD) market approached BCE in need of a custom high temperature heater solution. Their application involved a thin-film deposition using a sequence of various chemical processes. Repeating these processes results in a thin film being slowly deposited.  |

| Click for larger view. |

|

| 300mm Hot Chuck Heater with Mirror Finish |

|

| Click image for larger view. |