|

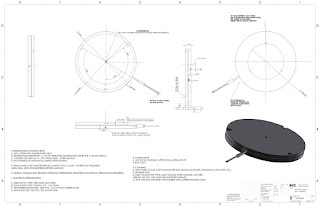

| 300mm Hot Chuck Heater with Mirror Finish |

To increase the speed at which a physical or chemical reaction takes place, heat is applied at various stages of the process. Heat is applied through the use of heated chucks which provide precise thermal uniformity which, as mentioned above, is critical for production.

|

| Click image for larger view. |

to replace a cast aluminum heater plagued with surface finish problems. Poor surface finish equates to poor thermal uniformity and heat transfer. To add insult to injury, the vendor was quoting extremely long lead-times for replacements.

Using their broad experience in semiconductor chuck heater design, BCE knew immediately the best solution would be a vacuum brazed-in 6061 T6 aluminum heater with a 2-3 Ra μin surface.

Specification to be met:

- Temperature uniformity +/- 1%

- 350°C - 450°C Temperature range

- Surface finish of 2-3 Ra μin

- Hard coat Anodize

- 6061 T6 Aluminum

- Be able to heat ceramic top plate

- 20 Meg-ohm isolation at 1000 VDC

- Hi-pot 2E + 1K at 3mA

BCE designed a chuck heater using their own proprietary internal element patterns, notches, and thermocouple holes, as well as adding additional manufacturing processes to provide the 2-3 Ra μin finish. Vacuum integrity for the customer has been greatly increased as well as contact with the ceramic workpiece and temperature uniformity.

For more information, contact BCE by calling 510-274-1990 or through visiting their website at https://bcemfg.com.