|

| Clean fluid, flow-through heating system. |

Electric heaters used in these applications must be compact, lightweight, and made of materials that won't contaminate samples. They also must be fast responding and provide large amounts of power when required.

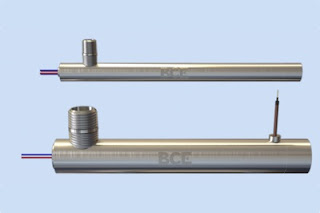

BCE, a Northern California manufacturer of custom electric heating elements, developed their "Mini Clean Flow" heater for these types of applications. The Mini Clean Flow is a very compact, fast responding electric heating element designed for applications where the heating of clean fluids is required, most often in the semiconductor, medical, and laboratory equipment industries. Designed with high power ratings wrapped in a small package, these specialized heaters offer ultra-fast heat-up and precise, accurate temperature control.

Mini Clean Flow heaters combine inlet and outlet connections along with a baffled stainless steel enclosure, creating a turbulent flow pattern for efficient heat transfer. Sealed resistance heaters are used to isolate process fluids from having contact with the elements directly. Internal thermocouples provide for outlet temperature regulation as well as for maximum sheath temperature control. The Mini Clean Flow's advanced mechanical design, along with its high power density and overall low mass, provides the end-user with a very efficient and precise heating solution.

For more information, contact BCE.

Phone: 510-274-1990

Web: https://bcemfg.com/minicleanflow