|

| Custom heater for vacuum applications with thermowell and multiple RTD sensors. |

Original equipment manufacturers (OEM's) of analytical, semiconductor, biomedical, life-science, and aerospace equipment continually design new equipment to apply and leverage these discoveries. Pressure to produce new machines offering greater efficiencies, compactness, and greater production is always present. Each item in the precedent design undergoes scrutiny and very often has be modified to a new fit, form, or function. New components are needed to meet the new design requirements.

The application of localized electric heating elements is one area that OEM design engineers find themselves navigating in unchartered waters. Very logically, they often attempt to use an off-the-shelf cartridge, silicone rubber, or mica heaters for their specialized heating requirement. Unfortunately this approach leads to compromises in layout, packaging, and performance. A much better alternative is considering a custom heating element, developed in consultation with an experienced custom heater manufacturer.

|

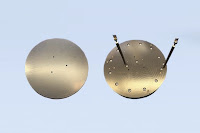

| Custom semiconductor wafer chuck heater. Highly uniform heat with no brazing or casting. |

- Front-end, practical design review to optimize manufacturability.

- Timely prototype development.

- Partnerships and alliances with platers, brazers, casters and heating element manufacturers.

- Single source responsibility.

- Testing, calibration, and QC.

- Inventory management.

- Value-added assembly.

|

| APCI Heater/Capillary Source Heater 400 deg. C, connector plug, and internal RTD sensor. |

By choosing a custom electric heating element design, the OEM gets exactly what they need in terms of form, fit, and function plus scores of other benefits derived from the heater vendor's tacit knowledge and past experiences.