Many types of OEM equipment, including medical, analytical, semiconductor, aerospace and laboratory test equipment, require a leak-proof penetration into a vacuum or pressure chamber. The device that accommodates this penetration is referred to as a

feedthrough (sometimes spelled "feedthru"). For the most part feedthroughs allow electrical currents or voltages into the vacuum or pressurized area. There are also many other non-electrical requirements for pressure/vacuum vessel penetration. Some examples of non-electrical penetrations are fiber-optic, fluid tubing bundles, and process control sensors such as thermocouples.

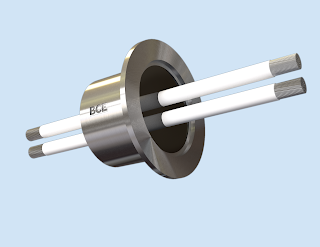

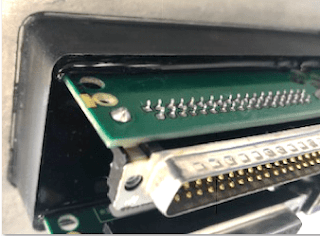

Multi-pin Threaded or Flanged Feedthroughs

Multi-pin Threaded or Flanged Feedthroughs

Multi-pin feedthroughs have circular flanged or threaded connectors for moderate pin density. They are typically offered with differing numbers of pins (often, 3, 5 or 7) and rated to 3.5 amps and 500 volts per pin. There are both single-ended and double-ended versions which offer a connector for the air side or both air and vacuum side connectors respectively.

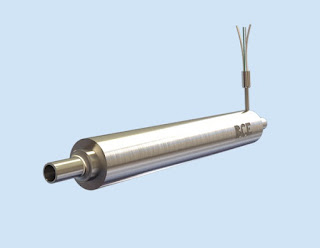

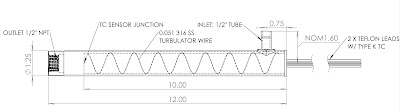

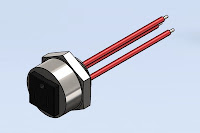

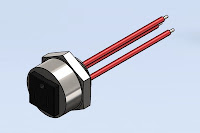

Thermocouple Feedthroughs

Thermocouple Feedthroughs

A thermocouple feedthrough is an electrical vacuum feedthrough commonly used for systems involved in temperature measurement. The thermocouple feedthrough itself doesn’t measure temperature, but is used to conduct the voltage signal from the vacuum to an external device. These are suitable for use in ultra-high vacuum applications.

High Power Feedthroughs

High Power Feedthroughs

High power electrical feedthroughs transmit high current and/or high voltage into a vacuum system. Variations of power electrical feedthroughs offer a range of current and voltage.

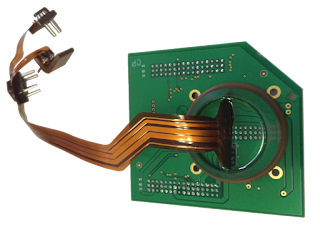

Epoxy Potted Feedthroughs

Epoxy vacuum feedthroughs offer the best application flexibility, they are cost competitive, and they have a high vacuum performance for today’s fast moving markets. Clear epoxy feedthroughs allow for the visual inspection of your components. They are board mountable with high vacuum performance and very competitive pricing compared to ceramic and metal seals.

Fiber Optic Feedthroughs

Fiber Optic Feedthroughs

Fiber Optic Feedthroughs provide the interface between fiber optics and UHV technology. They allow fiber optic cables are designed for vacuum applications requiring fiber optic connections from inside a vacuum system to external equipment.

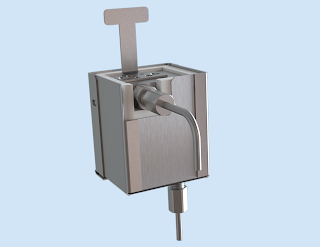

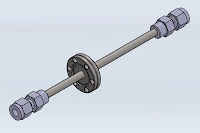

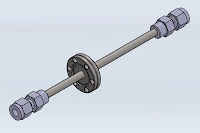

Fluid Feedthroughs

Fluid Feedthroughs

Also referred to as fluid feedthroughs, they are designed for the transmission of gases or coolants into high and ultrahigh vacuum environments. Generally constructed from 300 series stainless steel, they are available in single or multi-tube configurations.

Many accessories are available to be used in conjunction with the wide variety of vacuum feedthroughs. These included vacuum connectors, connectors, insulated wire, cable assemblies, insulators, and spacers, just to name a few.

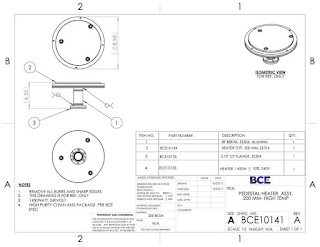

Specialized feedthroughs may be needed if your application includes cryogenic or very low temperatures, high temperatures, aggressive chemicals, or high pressure. Contact

an experienced manufacturer who specializes in vacuum feedthroughs to discuss which feedthrough will best meet your needs. A company worth their salt should be able to discern which would be the best fit with minimal hassle.