An instructional blog about specialized electric heating elements and vacuum feedthroughs for the OEM, analytical, semiconductor, aerospace, pharmaceutical, chemical, water, environmental, food processing, and alternative energy markets. Please feel free to contact us at (510) 274-1990 with any questions. BCEmfg.com

HK 300mm Compressed Heater Chuck

BACKGROUND

To reduce the overall cost for an existing application, BCE developed a 300mm aluminum heater chuck that is un-brazed utilizing the compression of two plates with countersink set screws. The heater surface specs were 0.003” flatness at a 0.005” parallelism. Using a 208-volt power supply at 9.7ohm, start @ 25°C temperature and ramped from 100°C to 465°C in 23 minutes.

SCOPE

Aluminum Heater Chuck needed to satisfy the following:

- Achieve temperature up to 435°C @ +/- 2% or better

- Internal element must be able to withstand temperatures up to 600°C

- Anodized surface for electrical isolation

- 208 Volt, 9.7 Ohm, 4,460 Watt (+5% / - 10%)

- Thermocouple bore hole to be placed at the center (variable)

- 4 point temperature profile on the top surface of the heater

- Used an infrared sensor for each 4 point locations

- FINISH: Hard coat anodize per MIL-A-8625F, Type 3 Class1 Hard-coat thickness

OUTCOME

BCE produced a highly effective high 300mm heater with exceptional uniformity better than the proposed 435°C (+/-2%). After the initial ramp, the heater maintained 435°C (+/- 1%) as per the chart below (Temp profile #5).

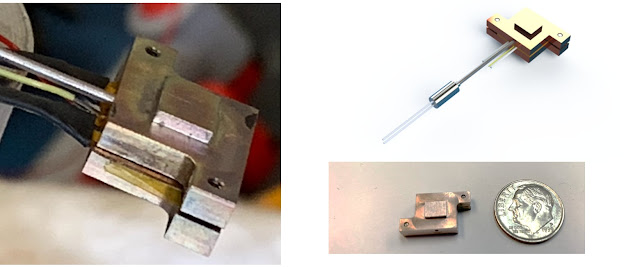

Molybdenum-Copper Stage Heater

BACKGROUND

A research and development company approached BCE wanting to heat a 1mm x 1mm x 0.5mm thick component. This was a very sensitive part that needed to be tested to a maximum exposure of 200°C continuous with very precise temperature uniformity for sampling purposes.

SCOPE

Molybdenum-Copper Stage Heater needed to satisfy the following:

- Temperature <201°C

- Internal element must be able to withstand temperature <210°C

- A cold section was not needed

- Molybdenum-Copper (Moly-Copper) base 65% Moly and 35% Copper

- 12Volt, 3Watt (Max)

- Two thermocouple type “K” external

- M1 threads

OUTCOME

BCE produced a highly effective assembly which reached the temperature of 200°C in under 1-Minute utilizing only 2.6 watts. Because of the low mass and high conductivity of the copper-moly base, reaching the target temperature and cooling down was highly efficient.

There were two thermocouples which were used to verify the test temperature. One was an exposed bare-bead TC 36 AWG, with the second TC being a 0.062ӯ probe style unit. The M1 threads were challenging, however our process was able to make this happen.

GET MORE INFORMATION ABOUT THE CUSTOM MOLYBDENUM-COPPER HEATER HERE

Call BCE today for more information.

510-274-1990

https://bcemfg.com