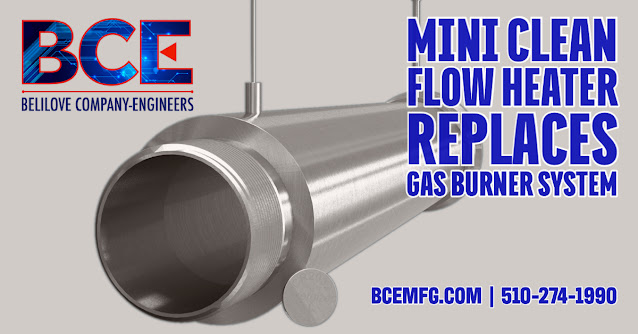

The application involved using environmentally friendly electric heat replacing a gas burner type system. The engineering request was to conform to a direct replacement 3” stainless tubing while utilizing BCE’s Mini Clean Flow In-line design. The challenge was building the right inlet and outlet fittings in-line for a seamless change in the air heating process (gas to electric). Electrically isolated elements in the air stream were required with a high temperature thermocouple assembly near the outlet.

- Temperature 482°C to 648°C

- Internal element must be able to withstand temperature <750°C and be electrically isolated

- 3” outside diameter, no insulation

- A sanitary fitting on the inlet with an NPT on the outlet

- A cold section on the heat source was required with fiberglass leads

- 304 stainless steel material on the heat source and vessel

- Type “J” Thermocouple able to withstand high temp at the outlet

- 480Volt, 7,000Watt (+/-10%)

BCE produced a highly effective Mini Clean Flow heater meeting the delta “T” requirements during the final testing. We were able to pressure test the part to 90PSI @ 20⁰C-25⁰ without any visible leaks in the weld or braze joints. A thorough quality inspection was completed on the heater source with final cleaning using isopropyl alcohol and dry air.