|

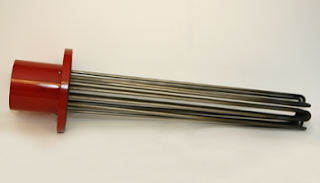

| Flanged Tubular Electric Heater Assembly Hotwatt |

Tubular elements are a common form of electric heater. Essentially a metal tube with resistance wire and electrical insulation inside, tubular elements can be configured into almost uncountable shapes and sizes. Manufacturers typically offer a range of standard sizes and ratings, but that should never deter you from making contact to discuss your ideas for a custom arrangement.

Two mounting schemes that are readily used on tanks or other vessels are the screw plug and flanged heater assemblies. In each case, tubular heaters are bent in a "U" shape and fitted into either a pipe flange or a threaded plug. A junction box encloses the electrical terminations for the heating elements, providing a single ended assembly that can be easily mounted to an industrial standard mechanical connection. These assemblies are useful for tank or vessel OEMs that wish to provide a fluid heating option to their customers.

|

| Examples of Screw Plug Electric Heaters Hotwatt |

Electric heat enables a properly configured controller to proportion heat into a subject fluid across a wide range, from very small packets that could be fractional percentages of full capacity to the fully available output of the heater. The units are compact, rugged, and can be configured to accommodate a broad array of industrial environments and applications.

Selecting or specifying a unit is uncomplicated. Determine the amount of heating capacity needed, then select the assembly mounting type (flange, screw plug, or other). Select an element sheath material that is compatible with the process media and a termination enclosure that suits the surrounding environment. Application assistance is available from product specialists who are well versed in the available options and can help you specify an assembly that provides excellent performance and an extended service life.