|

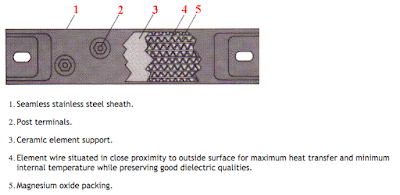

| Internal view of swaged cartridge heater. |

At the heart of most resistance type electric heaters is a nichrome alloy wire, or ribbon, referred to as the heating "element". It acts as a resistor to the electrical current and gives off heat. With sheathed heaters, the heating element is then wrapped in some sort of electric insulating material such as mica or magnesium oxide (MgO), and then encased in a metallic sheath. Unfortunately, both the electric insulator and the metallic sheath act as heat insulators to some degree, which cause the nichrome wire to get very hot. Nichrome wire has a melting point of 1400 deg. C (about 2500 degrees F). While this sounds high, the wires and ribbons can easily exceed these temperatures in normal operation when not allowed to adequately conduct heat.

Very often electric heater failure can be directly attributed to poor conductivity between the heating element and the process medium. Whether it be a cartridge, strip, band, duct or immersion heater the principle is the same - lower resistance wire temperatures equal longer heater life.

When applying cartridge heaters, special care has to be taken to the bore tolerance of the hole where the heater is inserted. The tighter the bore tolerance, the more efficiently the high internal wire temperatures are conducted away. Tolerances of several thousandths of an inch can change the life expectancy of a cartridge heater significantly.

Strip and band heaters require tight, full surface area clamping to maximize life and performance, while duct heaters and immersion heaters require circulation to transfer heat away from the element, and keeping resistance wire temperature within reasonable operating limits.

|

| Internal view of band & strip heater. |

Any situation where the heater is exposed to a stagnant air gap (or stagnant fluids) will most likely result in over temperature of the wire and failure at that point. With this in mind, anyone applying traditional resistance type, electric heating elements must be very aware of maintaining very intimate contact between the heating element and the item or process being heated.

Whenever applying electric heating elements, the consultation of an applications expert is always recommended. They will be able to consider many other operational factors such as wire watt density, conduction properties, control scheme and overall thermal system dynamics.