|

| Rain Gauge Heater Combination |

However, rain gauge performance can be severely impaired in regions where extreme cold weather dominates. In fact, a leading manufacturer of aviation technology solutions approached BCE to develop a means to heat their tipping bucket rain gauges in regions impacted by heavy snowfall and freezing rain.

In order, for these rain gauges to remain operational, precipitation needed to be melted in the collection funnel, then remain fluid inside the gauge and finally drain with ease after the data had been collected without freezing with exposure to the outside air.

SCOPE

Electric heaters to be incorporated in the rain gauge needed to meet the following specifications:

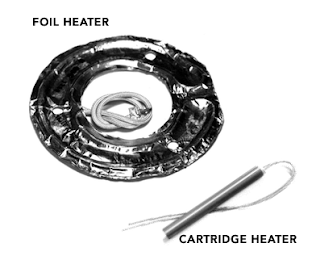

BCE proposed foil heaters to heat the collection funnel and the inside of the gauge. These heaters were precisely manufactured to achieve the perfect form and fit needed for the rain gauge components. Not only did they match the exact electrical specifications, the resistance element laminated between aluminum foil shells provided optimal surface heating. Furthermore, each of the foil heaters were also embedded with thermostats for accurate temperature control. For the drain tubes, BCE manufactured cartridge heaters to the desired length and with a robust stainless steel sheath providing continuous operation. These cartridge heaters further ensured maximum heat transfer through the close proximity of the element wire and sheath. This also allowed minimal internal temperatures in the cartridge heaters increasing heater life and preserving excellent dielectric strength, two essential criteria for this application. BCE’s contribution proved to be a huge success in the design and operability of these tipping bucket rain gauges.

SCOPE

Electric heaters to be incorporated in the rain gauge needed to meet the following specifications:

- All heaters needed to operate at 220V

- Heater used for collection funnel needed to operate at 160W

- Heater used for inside of gauge needed to operate at 130W

- 2 drain tubes required heaters to not exceed operation at 25W each

- Operating temperatures between -30°C to 45°C

- Temperature control required for heaters used in collection funnel and inside the gauge

- Temperature to remain approximately 15°C inside collection funnel

- Temperature to remain approximately 5°C inside gauge

- Heater used for collection funnel was not to exceed 8” in height and width

- Heater used for inside of gauge was not to exceed 11” in height and width

- Heaters used inside drain tubes needed to operate continuously and not exceed 20” in length

BCE proposed foil heaters to heat the collection funnel and the inside of the gauge. These heaters were precisely manufactured to achieve the perfect form and fit needed for the rain gauge components. Not only did they match the exact electrical specifications, the resistance element laminated between aluminum foil shells provided optimal surface heating. Furthermore, each of the foil heaters were also embedded with thermostats for accurate temperature control. For the drain tubes, BCE manufactured cartridge heaters to the desired length and with a robust stainless steel sheath providing continuous operation. These cartridge heaters further ensured maximum heat transfer through the close proximity of the element wire and sheath. This also allowed minimal internal temperatures in the cartridge heaters increasing heater life and preserving excellent dielectric strength, two essential criteria for this application. BCE’s contribution proved to be a huge success in the design and operability of these tipping bucket rain gauges.

Contact BCE for any electric heating design or application. You'll be pleased with BCE's experience, knowledge, and service. Visit them at http://belilove.com or call (510) 274-1990. Download the PDF Application Note here.