All of us at BCE wish our customers, vendors, and friends a very happy and prosperous 2018!

An instructional blog about specialized electric heating elements and vacuum feedthroughs for the OEM, analytical, semiconductor, aerospace, pharmaceutical, chemical, water, environmental, food processing, and alternative energy markets. Please feel free to contact us at (510) 274-1990 with any questions. BCEmfg.com

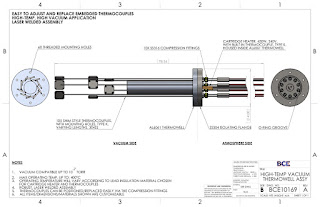

Electric Heating Element in Thermowell for Vacuum Applications, with Feedthrough and Multiple Thermocouple Sensors

|

| Click on image for larger view. |

The thermocouples can be easily mounted to any part in a vacuum chamber by the means of shims with mounting holes. Furthermore, they can be positioned with ease due to integrated compression fittings, which also allow for easy replacement of the thermocouples should the need arise.

A 304 Stainless Steel flange achieves a vacuum tight seal into any vacuum or degassing chamber port and there is virtually no outgassing, enhancing performance in high-vacuum environments.

Finally, a cartridge heater embedded inside an Aluminum 6061 thermowell allows for uniform and efficient heating of the chamber.

Scientists, researchers and engineers can all benefit from this high vacuum, barrier-breaking design.

For more information visit this link, or call BCE at (510) 274-1990.

Posted by

Belilove Company-Engineers

Labels:

electric heater,

thermowell,

vacuum,

vacuum feedthrough

Cartridge Heater Design

First, it's important to understand a very basic concept when applying electric heating elements. All electric heating elements need to move the heat away from the resistance wire into the surrounding media. This is done through conduction, convection, and radiation. Preventing resistance wires from getting too hot is the goal.

The difference comes down to internal design.

|

| Low watt density cartridge heater. |

|

| High watt density cartridge heater. |

High watt density cartridge heaters, capable of higher operating temperatures and long life include a different internal design, incorporating a swaging process and great care to resistance wire placement. High watt density heaters have very precisely wound nichrome resistance wire around the ceramic bobbin, and then, with exact centering and very tight tolerances, vibrate MgO into the metal tube surrounding the bobbin/wire core. Once the MgO is added, the heater goes through a swaging process that reduces the inner diameter of the metal tube. The result is compacted magnesium oxide with rock-like properties and much better thermal conduction from resistance wire to external heater sheath.

Both styles of cartridge heaters have their value and proper application. Using low watt density cartridge heaters on a simple applications like glue pots is fine, and will yield good life and performance. On the other hand, high temperature applications such as plastic injection mold machines require the higher performance and extended life that only a swaged heater will provide.

Contact BCE for more information on electric heating elements. Visit https://www.belilove.com or call (510) 274-1990.

Posted by

Belilove Company-Engineers

Aluminum Nitride Heating Elements

Aluminum nitride (AlN), a new generation of ceramic material, exhibits excellent performance for temperature, corrosion resistance, stability, high strength, and hardness. With the introduction of this new material to world of electric resistance heating element technology, AlN ceramic heaters are creating a good deal of excitement for equipment designers. AIN is opening new opportunities in power densities, space savings, and material compatibility.

Because they are capable of achieving up to 2000 watts per square inch, and operating temperatures of up to 1000 deg. C, AIN heaters show great promise for semiconductor processing applications such as crucible heating, fluid and gas handling and chemical vapor deposition. Able to operate in atmospheric and vacuum environments with excellent thermal efficiency, AIN heaters can also be designed with a multi-layer construction.

AIN heaters are ideal for applications that require very high watt density, and are an attractive alternative to traditional metal sheathed heaters that have limitations in thermal performance, material compatibility, fatigue, outgassing and thermal lag. AIN heaters are also resistant to most chemicals, acids and alkaline solutions.

These compact, robust heaters are an ideal solution for demanding thermal applications. Ceramic heaters can be custom designed to optimize thermal performance for the applications and RTD sensors can be deposited right on the ceramic heater itself for optimum control.

The most promising opportunities for AIN heaters exist in analytical instruments, semiconductor and medical equipment where high power densities, fast response, low mass, and corrosion resistance are often needed.

For more information on aluminum nitride heaters, or any custom thermal solution, contact BCE at https://www.belilove.com or call (510) 274-1990.

Because they are capable of achieving up to 2000 watts per square inch, and operating temperatures of up to 1000 deg. C, AIN heaters show great promise for semiconductor processing applications such as crucible heating, fluid and gas handling and chemical vapor deposition. Able to operate in atmospheric and vacuum environments with excellent thermal efficiency, AIN heaters can also be designed with a multi-layer construction.

AIN heaters are ideal for applications that require very high watt density, and are an attractive alternative to traditional metal sheathed heaters that have limitations in thermal performance, material compatibility, fatigue, outgassing and thermal lag. AIN heaters are also resistant to most chemicals, acids and alkaline solutions.

These compact, robust heaters are an ideal solution for demanding thermal applications. Ceramic heaters can be custom designed to optimize thermal performance for the applications and RTD sensors can be deposited right on the ceramic heater itself for optimum control.

The most promising opportunities for AIN heaters exist in analytical instruments, semiconductor and medical equipment where high power densities, fast response, low mass, and corrosion resistance are often needed.

For more information on aluminum nitride heaters, or any custom thermal solution, contact BCE at https://www.belilove.com or call (510) 274-1990.

Electric Heating Element Application and Engineering Reference Guide

Applying and specifying electric heating elements can be complicated. Make the job easier by downloading our handy reference guide (courtesy of Backer Hotwatt). The reference guide includes many of the electrical, mechanical, and physical properties you'll need to know when calculating wattage, evaluating maximum watt densities, and selecting proper heater placement.

Applying and specifying electric heating elements can be complicated. Make the job easier by downloading our handy reference guide (courtesy of Backer Hotwatt). The reference guide includes many of the electrical, mechanical, and physical properties you'll need to know when calculating wattage, evaluating maximum watt densities, and selecting proper heater placement.CONTENTS

- Wattage Calculation Formulas and Examples

- Properties of Metals

- Properties of Non-Metallic Solids

- Properties of Liquids and Gases

- Suggested Watt Densities

- Estimates of Wattage Required

- GuideforHeatLosses

- Suggested Sheath Materials

- Thermal Systems

- Installation

- Ohms Law

- Wiring Diagrams

- Mathematical Conversions

- Wire, Cable and Current Capacities

- Wire Gage Data

- Pipe Sizes and Threads

- Resistance Wire - Current vs. Temperature

Contact BCE for any electric heating element or thermal system requirement. Visit them at https://www.belilove.com or call (510) 274-1990.

Posted by

Belilove Company-Engineers

Labels:

Air Process Heaters. Cartridge Heaters,

Band Heaters,

Circulation Heaters,

electric heater,

Flexible Heaters,

Glasrope Heaters,

heating element,

Hotwatt,

Immersion Heaters,

Strip Heaters

High-Temperature Vacuum Feedthrough Assembly with Multi-Thermocouples and Electric Heater with Thermowell

|

| Multi-Thermocouple and Heater Feedthrough |

Specifications

- CAD modeling and Engineering Design Consultation

- High-Vacuum compatible up to 10-7 Torr

- Max Operating Temperature can be up to 400°C (dependent on lead insulation material)

- 10X thermocouples, Type K, Grounded, with shims and mounting holes (multiple options available)

- 450W, 240V embedded cartridge heater (multiple options available)

- 10X SS316 compression fittings (multiple options available)

- AL6061 thermowell

- SS304 Isolating Flange with dovetail O-ring groove

Posted by

Belilove Company-Engineers

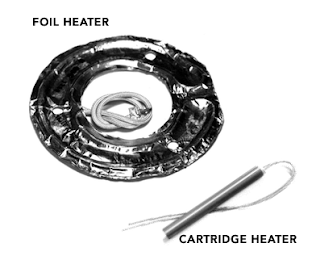

BCE’s Foil and Cartridge Heaters: Braving Extreme Weather Conditions in Rain Gauges

|

| Rain Gauge Heater Combination |

However, rain gauge performance can be severely impaired in regions where extreme cold weather dominates. In fact, a leading manufacturer of aviation technology solutions approached BCE to develop a means to heat their tipping bucket rain gauges in regions impacted by heavy snowfall and freezing rain.

In order, for these rain gauges to remain operational, precipitation needed to be melted in the collection funnel, then remain fluid inside the gauge and finally drain with ease after the data had been collected without freezing with exposure to the outside air.

SCOPE

Electric heaters to be incorporated in the rain gauge needed to meet the following specifications:

BCE proposed foil heaters to heat the collection funnel and the inside of the gauge. These heaters were precisely manufactured to achieve the perfect form and fit needed for the rain gauge components. Not only did they match the exact electrical specifications, the resistance element laminated between aluminum foil shells provided optimal surface heating. Furthermore, each of the foil heaters were also embedded with thermostats for accurate temperature control. For the drain tubes, BCE manufactured cartridge heaters to the desired length and with a robust stainless steel sheath providing continuous operation. These cartridge heaters further ensured maximum heat transfer through the close proximity of the element wire and sheath. This also allowed minimal internal temperatures in the cartridge heaters increasing heater life and preserving excellent dielectric strength, two essential criteria for this application. BCE’s contribution proved to be a huge success in the design and operability of these tipping bucket rain gauges.

SCOPE

Electric heaters to be incorporated in the rain gauge needed to meet the following specifications:

- All heaters needed to operate at 220V

- Heater used for collection funnel needed to operate at 160W

- Heater used for inside of gauge needed to operate at 130W

- 2 drain tubes required heaters to not exceed operation at 25W each

- Operating temperatures between -30°C to 45°C

- Temperature control required for heaters used in collection funnel and inside the gauge

- Temperature to remain approximately 15°C inside collection funnel

- Temperature to remain approximately 5°C inside gauge

- Heater used for collection funnel was not to exceed 8” in height and width

- Heater used for inside of gauge was not to exceed 11” in height and width

- Heaters used inside drain tubes needed to operate continuously and not exceed 20” in length

BCE proposed foil heaters to heat the collection funnel and the inside of the gauge. These heaters were precisely manufactured to achieve the perfect form and fit needed for the rain gauge components. Not only did they match the exact electrical specifications, the resistance element laminated between aluminum foil shells provided optimal surface heating. Furthermore, each of the foil heaters were also embedded with thermostats for accurate temperature control. For the drain tubes, BCE manufactured cartridge heaters to the desired length and with a robust stainless steel sheath providing continuous operation. These cartridge heaters further ensured maximum heat transfer through the close proximity of the element wire and sheath. This also allowed minimal internal temperatures in the cartridge heaters increasing heater life and preserving excellent dielectric strength, two essential criteria for this application. BCE’s contribution proved to be a huge success in the design and operability of these tipping bucket rain gauges.

Contact BCE for any electric heating design or application. You'll be pleased with BCE's experience, knowledge, and service. Visit them at http://belilove.com or call (510) 274-1990. Download the PDF Application Note here.

Posted by

Belilove Company-Engineers

Labels:

BCE,

cartridge heater,

electric heater,

foil heater,

rain gauge

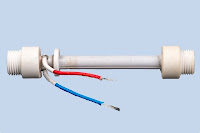

Simply-designed, Versatile and Robust Vacuum Feedthrough

BCE’s plug feedthrough is an ideal product for any vacuum application. Not only is it easy to install and withdraw due to its stainless steel, threaded plug body, it can be embedded with leads, thermocouples and RTDs. Thus, it can be designed and customized to meet all requirements at a low production cost.

As it is sealed with BCE’s proprietary epoxy meeting NASA ASTM E595, outgassing is excessively low. Furthermore, all leads come with standard KAPTON insulation to limit contamination in vacuum applications. It should be noted that the 316 SS construction allows it greater resistance to corrosion increasing product life. This means fewer replacements.

Specifications

As it is sealed with BCE’s proprietary epoxy meeting NASA ASTM E595, outgassing is excessively low. Furthermore, all leads come with standard KAPTON insulation to limit contamination in vacuum applications. It should be noted that the 316 SS construction allows it greater resistance to corrosion increasing product life. This means fewer replacements.

Specifications

- CAD modeling and engineering design consultation.

- Vacuum compatible to 10-9 ATM.CC/Sec.

- Max. operating temperature: 200°C.

- BCE proprietary epoxy meets NASA ASTM E595 low outgassing spec.

- Corrosion resistant.

- Embedded thermocouple(s), lead wire(s) and rtd(s) with kapton insulation (multiple options available).

- All dimensions, materials and features can be customized.

BCE’s Vacuum Ring Heater: Defying Boundaries in Degassing Chambers

|

| BCE Vacuum Ring Heater |

Providing uniform heat to semiconductor devices in degassing chambers is essential in extracting impurities. This can only be achieved if a heating device has the proper fit and temperature uniformity for a given chamber. It is for this very application that BCE was approached by a large semiconductor company from Silicon Valley. In order to heat this company’s semiconductor wafers, it was critical that the heating device be manufactured to fit precisely into a large and circular degassing chamber posing manufacturing challenges due to dimensional and application parameters. BCE was able to provide extensive design consultations, 3D CAD modeling and lean manufacturing capabilities to this semiconductor giant at a competitive price. All these services were rendered while catering to all requirements needed to successfully manufacture their products.

SCOPE

The heating apparatus needed to satisfy the following criteria:

- Vacuum compatibility to 10-8 Torr

- Maximum Operating Temperature: 200°C

- Temperature uniformity of ±4% at 150°C

- Operate at 1500W, 240V

- All epoxies used needed to meet NASA’s Low Outgassing Spec (ASTM E595)

- Reduced contamination from components inside chamber

- Temperature sensing capability

- Circular configuration between 34 and 36 inches in diameter

- Height of part was not to exceed 1 ft.

- Effective heat transfer from heating device with reduced machining cost

BCE’s Vacuum Ring Heater proved to be the ideal product for this application. Its strong aluminum ring construction ensured effective heat transfer to the circular wafers while keeping manufacturing costs low. Furthermore, its strategically embedded heater with stainless steel sheath allowed the device’s temperature uniformity to remain at ±2% at 150°C, greatly exceeding customer requirements. Moreover, BCE’s proprietary epoxy meeting NASA’s low outgassing spec was used as the primary sealant and KAPTON insulated leads were provided for the heater and integrated thermocouple to reduce contamination. In fact, the integrated thermocouple type K further served to monitor the temperature supplied to the chamber. Finally, all electrical, vacuum and dimensional requirements were met to provide the most optimal thermal environment.

Visit this link for more information on the Vacuum Ring Heater, or call (510) 274-1990.

Posted by

Belilove Company-Engineers

Labels:

BCE,

custom thermal systems,

electric heater,

outgassing,

semiconductor,

vacuum chamber,

wafer

Vacuum Thermowell and Heater Assembly Simultaneously Heats and Monitors Semiconductor Wafer's Temperature

BTU requirement and temperature control are critical in the fabrication of silicon wafers in the semiconductor industry. Seldom can a product provide both a thermally effective means to heat wafers and simultaneously monitor their respective temperature. BCE’s Vacuum Thermowell and Heater Assembly achieves both of these criteria. Its aluminum thermowell houses a cartridge heater capable of supplying uniform heat, which can be monitored through an embedded thermocouple.

Furthermore, a flange at the end of the thermowell allows for easy installation into any vacuum port and provides an effective seal via its dovetail O-ring groove. An aluminum construction further ensures that the entire assembly remains lightweight and inexpensive to machine, reducing overall product cost. Moreover, multiple RTDs are hermetically sealed into the thermowell to allow for precise temperature monitoring of wafers and other components while maintaining vacuum integrity. They can be positioned and designed for any application, as can the thermowell. In order to prevent any outgassing and minimize release of contaminants into the chamber, the RTDs are sealed using BCE’s proprietary epoxy meeting NASA’s low outgassing spec and are available with Kapton leads.

Check out the BCE Vacuum Thermowell & Heater Assembly web page for more detail.

Furthermore, a flange at the end of the thermowell allows for easy installation into any vacuum port and provides an effective seal via its dovetail O-ring groove. An aluminum construction further ensures that the entire assembly remains lightweight and inexpensive to machine, reducing overall product cost. Moreover, multiple RTDs are hermetically sealed into the thermowell to allow for precise temperature monitoring of wafers and other components while maintaining vacuum integrity. They can be positioned and designed for any application, as can the thermowell. In order to prevent any outgassing and minimize release of contaminants into the chamber, the RTDs are sealed using BCE’s proprietary epoxy meeting NASA’s low outgassing spec and are available with Kapton leads.

Check out the BCE Vacuum Thermowell & Heater Assembly web page for more detail.

SuperCirc Heater: Revolutionizing Thermal Efficiency in the Petrochemical Industry

One of the most effective ways to increase heating of plant utilities is by pre-heating combustion gases supplied to burners. This can be challenging especially when a small footprint, high thermal efficiency and low maintenance are required in very harsh environments. In fact, BCE was approached by an international petrochemical giant seeking to replace their line of cartridge heaters used for this very application. This multi-billion dollar oil and gas company was primarily concerned with improving thermal efficiency and heater life as heaters needed to be replaced often due to exposure to corrosive materials and high watt densities. Replacing these heaters was proving to be quite costly and a quick remedy was needed to allow for greater profit generation.

SCOPE

BCE proposed its SuperCirc heater as the most viable option for this dilemma. Its revolutionary fin design tripled thermal efficiency by tripling the heated surface area within the prescribed electrical and dimensional specifications. In effect, this resulted in decreasing the watt density from 36 W/in2 to 14 W/in2; greatly diminishing surface temperatures on the heater increasing heater life. Furthermore, not only was it able to ramp to 300°C in under 10 minutes exceeding customer expectations, its robust 316 stainless steel construction proved to be optimal in preventing heater degradation with exposure to harsh chemicals. Furthermore, an embedded, grounded, type K thermocouple provided accurate temperature monitoring, and the heater body inlet and outlet fit effortlessly into the existing BSP ports on customer site.

For more information, visit http://heater.beleilove.com or call 510-274-1990.

SCOPE

- The heater needed to meet the following requirements:

- Thermal efficiency needed to be tripled by reducing watt density

- 200W, 120V

- Heater sheath material capable of withstanding a corrosive environment

- Gas needed to be pre-heated to a temperature of 300°C

- 10 minute ramp time

- Gas flow needed not be exposed to any resistive material

- Built-in thermocouple for accurate temperature monitoring

- Easy installation into existing BSP threaded ports

- Heater body dimensions to not exceed 10” x 1” x 1” envelope due to space restriction

BCE proposed its SuperCirc heater as the most viable option for this dilemma. Its revolutionary fin design tripled thermal efficiency by tripling the heated surface area within the prescribed electrical and dimensional specifications. In effect, this resulted in decreasing the watt density from 36 W/in2 to 14 W/in2; greatly diminishing surface temperatures on the heater increasing heater life. Furthermore, not only was it able to ramp to 300°C in under 10 minutes exceeding customer expectations, its robust 316 stainless steel construction proved to be optimal in preventing heater degradation with exposure to harsh chemicals. Furthermore, an embedded, grounded, type K thermocouple provided accurate temperature monitoring, and the heater body inlet and outlet fit effortlessly into the existing BSP ports on customer site.

For more information, visit http://heater.beleilove.com or call 510-274-1990.

Posted by

Belilove Company-Engineers

Labels:

BCE,

electric heater,

gas heater,

heater,

pre-heater,

SuperCirc

Example of a Large Vacuum Chamber Used at NASA

Facility 238 is a large, vertical, cylindrical thermal vacuum chamber which is used for thermal vacuum and thermal balance testing, and baking out spacecraft hardware. Test articles are normally loaded through the top of the chamber using the building crane; however, small payloads can be transported through the personnel entrance. Ports for electrical feedthroughs, liquid/gas feedthroughs, and viewing are located around the perimeter of the chamber. A clean tent at the chamber entrance provides class 10,000 cleanliness conditions.

Mode of Operation

With the chamber dome rolled back, the overhead crane is used to lower the payload onto the support fixture. In most cases, special fixturing must be designed due to the uniqueness of the test article support system. Once installed, the payload is instrumented and connected to the ground support equipment via feedthroughs. Access to the chamber is throught a clean tent. The use of cleanroom procedures and the wearing of clean garments are required when working in the chamber.

Initial chamber evacuation is provided by two rotary piston mechanical pumps, with four closed cycle cryopumps for high vacuum pumping. Each cryopump is isolated from the chamber by a sliding gate main valve to allow off-line cool down and regeneration.

Parameters

Mode of Operation

With the chamber dome rolled back, the overhead crane is used to lower the payload onto the support fixture. In most cases, special fixturing must be designed due to the uniqueness of the test article support system. Once installed, the payload is instrumented and connected to the ground support equipment via feedthroughs. Access to the chamber is throught a clean tent. The use of cleanroom procedures and the wearing of clean garments are required when working in the chamber.

Initial chamber evacuation is provided by two rotary piston mechanical pumps, with four closed cycle cryopumps for high vacuum pumping. Each cryopump is isolated from the chamber by a sliding gate main valve to allow off-line cool down and regeneration.

Parameters

- Test Pressure: 5 x 10-7 mmHg

- Shroud Temperature: GN2 mode -90°C to +90°C , LN2 mode -190°C

- Chamber Pump: 4 cryopumps

- Test Volume: 12' x 15'

- Payload Support: Floor level - 4' square platform

- Side Wall: Hardpoints at 6' and 12' levels

- Crane Capacity: 5 tons Viewports: 9" diameter

- Standard Electrical Feedthroughs: 36 - 37 pin connectors (RF feedthroughs available on request)

- Pressure: Capacitance manometer - Atm to 10-3 mmHg

- Ion Gauge: 10-3 mmHg to ultimate

- Payload Temperature: 324 channels of thermocouple or thermistor channels

- Contamination Monitor: TQCM, coldfinger, residual gas analyzer

Custom Heating Element for Lab Mice Stabilization During MRI

|

| Custom electric heating element developed for keeping mice warm during MRIs. |

Compatibility between MRI machines and resistive, electric heaters has been a challenge to manufacturers of heating devices. MRI's and electric heaters don't like each other because of the electromagnetic field given off by DC and standard AC voltages. That E/M field disturbs the image resolution and quality of the MRI.

In research and lab testing, mice and other rodents are examined via MRI technology. In order for the rodents to be compliant with the testing procedure, the mice are given anesthesia which lowers their body temperatures and can send them into hypothermia. In the past, this situation was corrected by warming the air around the animal sufficiently to warm their body. Air heating requires a significant amount of valuable space, so a different heating source that would both not conflict with the MRI output and also provide a more compact, economical solution was required.

While DC voltages and standard AC voltage caused problems with the MRI, the solution turns out to be a copper wire element, embedded in heating blanket, and powered by AC voltage in a frequency ranging between 10-100 kHz.

In research and lab testing, mice and other rodents are examined via MRI technology. In order for the rodents to be compliant with the testing procedure, the mice are given anesthesia which lowers their body temperatures and can send them into hypothermia. In the past, this situation was corrected by warming the air around the animal sufficiently to warm their body. Air heating requires a significant amount of valuable space, so a different heating source that would both not conflict with the MRI output and also provide a more compact, economical solution was required.

While DC voltages and standard AC voltage caused problems with the MRI, the solution turns out to be a copper wire element, embedded in heating blanket, and powered by AC voltage in a frequency ranging between 10-100 kHz.

Conclusion

High frequency electrical heating provides a simple means by which stable body temperatures can be maintained in the mouse. The space requirement for the heating apparatus around the mouse is minimized and the system can be extended to use arbitrarily shaped resistor systems. Image and spectral quality are not adversely affected by the presence of the AC used in the heater so MRI performance is not compromised. As such a new MRI-compatible mouse heating system has been developed and validated.

To read the entire article, An MRI-Compatible High Frequency AC Resistive Heating System for Homeothermic Maintenance in Small Animals, visit this link.

Posted by

Belilove Company-Engineers

Labels:

bio-science,

custom heating element,

lab heater,

research

Polyimide Thermofoil Heaters Used for Space Applications

Thermofoil heaters of an all polyimide (adhesive-less) construction are used for high reliability space applications. They are ideal for extreme temperature fluctuations and have high tear and tensile strength. The specifications for the design and manufacture of these heaters are rigidly controlled, and rightly so. These heaters often perform critical heating application on satellites and other space craft.

Construction

Lead Wires

Lead wires must be a minimum of 26 gauge when using high strength copper alloy conductors, and 24 gauge for all other copper conductors. Lead wire insulation must consist of polyimide (Kapton), polytetrafluoroethylene (PTFE/Teflon), or ethylene-tetrafluoroethylene (ETFE) materials.

Lead Termination

Construction

A polyimide (Kapton) is used as the heater base material, also known as the substrate or mounting surface. A second polyimide layer over the heating element provides a protective enclosure.

Heater Element

Heater Element

The heating element is made of a Ni-600 Inconel (nickel-chromium-iron) alloy. Single or dual resistive elements may be used in the design, but the element must be must be of a single layer in cross-section. The element are normally an etched foil design with uniform in cross-section, and they have a minimum trace width of 0.010 in. (0.0254 cm) by design. Spacing between foil traces is tightly controlled and must not be less than 0.010 in. (0.0254 cm). The spacing between the outer foil trace and the heater edge (border trim) also cannot be less than 0.010 in. (0.0254 cm).

Lead wires must be a minimum of 26 gauge when using high strength copper alloy conductors, and 24 gauge for all other copper conductors. Lead wire insulation must consist of polyimide (Kapton), polytetrafluoroethylene (PTFE/Teflon), or ethylene-tetrafluoroethylene (ETFE) materials.

Lead Termination

The termination of the lead wire has to be welded and contain a minimum of two weld points between the lead wire and landing bond pad. Lead wire terminations also need to be enclosed in a hardened Hysol epoxy potting, in order to secure lead wires to the heater so that lead pull stresses are not transmitted to the weld joint.

Power Rating

Polyimide thermofoil heaters used for space have a maximum power rating of 4.5 W/in2 (0.7 W/cm2) when suspended in still air at 25°C, although this specification is for test purposes only and is not indicative of the maximum power rating in application (with heater mounted to a heat sink). Actual rated power (or voltage) are specified in each application.

Visit this web page to view or download the entire NASA General Specification for Thermofoil Heater, All- Polyimide, Space Applications.

Rapid Response Electric Heaters Designed for Clean Gases and Liquids

|

| Mini Clean Flow Heater |

The use of standard screw plug immersions heaters, screwed into a stainless steel welded vessels (known as circulation heaters) are almost always a misapplication for these unique requirements. Circulation heaters create more problems due to leaks, material compatibility, poor controllability, and bulky size.

BCE, a northern Californian manufacturer of custom heating elements offers it's Mini Clean Flow Heater specifically for these applications. These heaters are designed for heating "clean" liquids and gases normally found in fuel cell, bio-med, laboratory, food, semiconductor and pharmaceutical applications.

The Mini Clean Flow Heater operates in a liquid or gas stream providing very fast response times and accurate control capability.

The heating elements in the Mini Clean Flow Heater are isolated electrically from the process media, protecting them from contaminants and providing long life.

Summary:

- Designed for heating of clean gases or liquids

- Gas flow passes over an enclosed heated body; not exposed to resistive elements (Nichrome)

- All parts exposed to gas flow are constructed of 304 stainless (other material available)

- High temperatures

- Custom wattages, voltages, inlet and outlet fittings (NPT, SAE, BSP &VCR) are available.

- Made in U.S.A.

For more information, visit http://heater.belilove.com

Posted by

Belilove Company-Engineers

Labels:

clean gases,

custom heating element,

custom thermal systems,

electric heating elements,

Mini Clean Flow Heater

Custom Electrical, Pneumatic, and Optical Feedthroughs

Equipment manufacturers and scientific researchers are continually challenged with supplying power, fiber-optic, control, and monitoring cables into (and out of) sealed vacuum vessels. Whether due to space restrictions, special geometries, or number and type of conductors, standard glass-to-metal or ceramic feedthroughs never quite fit the bill. Unfortunately, because of limited options, many designers are forced to compromise and go for an off-the-shelf solution.

You don't have to fit a square peg in a round hole anymore. Choose BCE custom feedthroughs for your next design.

http://www.belilove.com/feedthrough

You don't have to fit a square peg in a round hole anymore. Choose BCE custom feedthroughs for your next design.

http://www.belilove.com/feedthrough

(510) 274-1990

Posted by

Belilove Company-Engineers

Labels:

BCE,

electrical feedthrough,

epoxy electrical feedthrough,

fiber optic,

optic feedthrough,

pneumatic feedthrough,

vacuum

Kapton (Polyimide) Etched Foil Heating Elements

|

| Kapton (Polyimide) Etched Foil Heating Element. |

Kapton etched foil heating assemblies are constructed from a very thin etched foil circuit embedded between two layers of Kapton, or one layer of Kapton and some other material (such as alumina.) The result is a heater with features perfect for a wide variety of industries - from aerospace, to medical and scientific equipment, to research & development applications.

Kapton heaters provide excellent heat transfer to adjoining surfaces with the release of minimal contaminants through the use of this very low mass, low outgassing, high dielectric material. They provide very even heat distribution extremely fast heat-up and cool-down rates. Additionally, they can be constructed in just about any shape, size, wattage or voltage. They are also ideal for applications where distributed wattage (heating profile) is required.

Furthermore, when the heater and ceramic insulator is bound in such a way to meet NASA’s low outgassing specification, Kapton heater assemblies are ideal for use in vacuum applications.

Posted by

Belilove Company-Engineers

Labels:

BCE,

electric heat,

flexible heater,

heater,

heating element,

Kapton,

Polyimide

9 Pin Vacuum Feedthrough: UHV Compatible Technology Serving the Semiconductor Industry

Some of the most stringent tolerances and vacuum requirements exist in the ever-expanding semiconductor industry. Tight restrictions in vacuum ports, high temperature applications and exposure to high stress environments further add to the challenge of designing an electrical feedthrough that can be manufactured quickly and installed with ease. An American multinational manufacturer of chips and microprocessors approached BCE with these exact requirements in order to replace their existing vacuum feedthroughs incapable of providing an adequate performance in ultra-high vacuum environments. Furthermore, their existing supplier had long lead times and the procured feedthroughs needed to be replaced often as their contacts would fail due to oxidation formation on the conductive layer.

SCOPE

All customer requirements were exceeded by BCE’s 9 pin vacuum feedthrough. Not only did it meet all electrical and configuration specifications, it provided a vacuum compatibility twice as much as that required by the customer allowing them to expand their capabilities to higher vacuum thresholds. It also remained operable at higher temperatures, nearing maximums of 300°C. Furthermore, the gold plated pins proved to be ideal in the prevention of oxidative layers inhibiting current flow. Moreover, BCE’s proprietary ceramic seal achieved the desired robustness and allowed the feedthrough to remain operable under high stress conditions. Finally, the client was equally impressed by BCE’s quick-turnaround time and competitive pricing.

SCOPE

- The feedthrough needed to satisfy the following requirements:

- Ultra-High Vacuum (UHV) compatibility up to 1 X 10-10 atm.cc/sec

- Remain operable at temperatures exceeding 250°C

- Pins preventing oxidation of conductive layer for longevity

- 9 pin feedthrough configuration

- Voltage requirement: 750 AC RMS

- Current requirement: 7 AMPS

- Quick-turnaround on feedthrough manufacturing

- Robust seal withstanding high stress environments

- Ease in installation, simple design

- Low cost for application

All customer requirements were exceeded by BCE’s 9 pin vacuum feedthrough. Not only did it meet all electrical and configuration specifications, it provided a vacuum compatibility twice as much as that required by the customer allowing them to expand their capabilities to higher vacuum thresholds. It also remained operable at higher temperatures, nearing maximums of 300°C. Furthermore, the gold plated pins proved to be ideal in the prevention of oxidative layers inhibiting current flow. Moreover, BCE’s proprietary ceramic seal achieved the desired robustness and allowed the feedthrough to remain operable under high stress conditions. Finally, the client was equally impressed by BCE’s quick-turnaround time and competitive pricing.

Posted by

Belilove Company-Engineers

Labels:

BCE,

electrical feedthrough,

epoxy feedthrough,

semiconductor,

vacuum

Video: Flanged, Replaceable, Multi-Thermocouple Electrical Feedthrough

With most vacuum feedthroughs, troubleshooting can be difficult as well when multiple fixed elements are involved. If one element fails, generally the entire vacuum feedthrough is rendered useless. With BCE’s Multi-TC, Flanged Feedthrough, arduous troubleshooting procedures are a thing of the past. In fact, this feedthrough’s thermocouples are replaceable as they can be extracted from the compression fittings with great ease. This means that if thermocouples fail, they can be removed, tested and replaced within minutes. Thus, this no-hassle design allows for faster, more accurate and more cost-effective thermal data collection. Trust BCE’s Multi-TC, Flanged Feedthrough for your most complicated thermal detection needs. Contact BCE for more information.

Posted by

Belilove Company-Engineers

Replaceable, Flanged, Multi-Thermocouple Vacuum Feedthroughs

|

| (Click for larger view) |

With most vacuum feedthroughs, troubleshooting can be difficult as well when multiple fixed elements are involved. If one element fails, generally the entire vacuum feedthrough is rendered useless. With BCE’s Multi-TC, Flanged Feedthrough, arduous troubleshooting procedures are a thing of the past. In fact, this feedthrough’s thermocouples are replaceable as they can be extracted from the compression fittings with great ease. This means that if thermocouples fail, they can be removed, tested and replaced within minutes. Thus, this no-hassle design allows for faster, more accurate and more cost-effective thermal data collection. Trust BCE’s Multi-TC, Flanged Feedthrough for your most complicated thermal detection needs.

Specifications

- Replaceable thermocouple(s) design

- Vacuum Integrity: 10-8 atm.cc/sec

- Multiple types and lengths available for thermocouple(s)

- Multiple types and sizes available for flange(s)

- Multiple types and sizes available for lead wires (KAPTON available for minimal contaminant release)

- Compatible O-rings available for flange(s)

- Can be adapted to virtually any temperature range

For more information, visit http://www.belilove.com/feedthrough.

Posted by

Belilove Company-Engineers

BCE’s Optic Cable Feedthru: The Source For Accurate Spectrometer Data Collection

|

| BCE Optic Cable Feedthru |

SCOPE

The feedthrough needed to meet the following specifications:

- Ultra-high vacuum compatible to 1X10–9 cc/sec of He @ 1 ATM

- Ease of installation into vacuum chamber wall

- Offer a high coupling efficiency into spectrometer

- Compatible connection with computing devices

- Remain operable under 100 psi of static pressure

- Be able to sustain pressures ranging from 500 to 1000 psi

- Adapt quickly, within milliseconds, to varying pressures

- Fit easily into restricted spaces

- Prevent release of contaminants via outgassing

BCE proposed its Optic Cable feedthrough as the ultimate solution to this design conundrum. The flexible stainless steel conduit of the fiber optic cable along with its connectors coupled easily with the spectrometer and company devices. The CF flange of the feedthrough mounted effortlessly into the vacuum chamber wall and BCE’s proprietary epoxy seal meeting NASA ASTM E595 allowed for less than 0.1% of volatiles to emanate into the environment and with less than 1% of mass loss. Further testing of BCE’s optic cable feedthrough at the client facility revealed that it remained operable at varied, high pressures while ensuring an ultra-high vacuum seal.

BCE’s Mini-Clean Flow (MCF) Heater at the Core of 4D Entertainment

|

| BCE Mini Clean Flow (MCF) Heater |

SCOPE

The heater of the apparatus needed to be able to:

- Generate internal temperatures exceeding 500°C

- Ramp to elevated temperatures within minutes

- Operate at low voltage: 24V

- Sustain pressures up to 80 psi

- Assemble easily to a control valve

- Remain operable at a motion of 10 g

- Allow for acute temperature control

- Have a low mass design for efficient heat transfer

- Be compact; allowing the assembly to remain within a 10” envelope

BCE’s MCF heater provided the optimal solution to this design challenge. During pre-heat with no air flow, the internal temperature of the MCF reached 320°C. After an 80 psi air burst and temperature drop, the low mass of the heater was able to achieve an internal temperature of 505°C in just under 90 s during the heat effect. This greatly surpassed customer expectations. Not only was its compactness an asset in maintaining the dimensional restrictions, its unique design with NPT fitting assembled easily to other components. Moreover, the built-in thermocouple type K offered precise temperature monitoring for this sensitive application. Finally, its robust design allowed for continuous operation under the most strenuous pressures and motion.

NASA Preferred Reliability Practices: Vacuum Seals Design Criteria

From the Office of The Chief Engineer at NASA - NASA's Preferred Practices.

Courtesy of BCE (Belilove Company-Engineers).

Courtesy of BCE (Belilove Company-Engineers).

Welcome to BCE

BCE (Belilove Company-Engineers) has over 60 years experience as a California based manufacturer, value added component integrator, and distributor serving the analytical instrumentation, semiconductor, photovoltaic, medical equipment, plastics processing, foodservice equipment, packaging, and aerospace industries.

BCE offers custom electrical heaters, sensors, controls and custom vacuum feedthroughs for sale. Supported by their wealth of knowledge and experience, BCE will assist you with your electric heating, vacuum feedthrough, and ceramic substrate needs.

http://www.belilove.com | (510) 274-1990

Posted by

Belilove Company-Engineers

Labels:

custom heating element,

electric resistance heating,

electrical feedthrough,

epoxy vacuum feedthrough,

heater,

thermal system

Vacuum Technology and Vacuum Design Handbook for Accelerator Technicians

A handbook titled "Vacuum Technology and Vacuum Design Handbook for Accelerator Technicians" published in 2011 and downloaded from the Lawrence Berkeley National Laboratory website, is a compilation of information gathered from over 50 years of direct hands-on experience to applicable information widely available from the vacuum technology industry.

It seeks to address common and specific vacuum technology problems while clarifying the design standards and philosophies adopted for use in the ANSTO accelerator facilities.

Posted by

Belilove Company-Engineers

Labels:

electrical feedthrough,

epoxy feedthrough,

vacuum feedthrough,

Vacuum Technology and Vacuum Design Handbook for Accelerator Technicians

Happy Fourth of July from BCE

"We hold these truths to be self-evident, that all men are created equal, that they are endowed by their Creator with certain unalienable Rights, that among these are Life, Liberty and the pursuit of Happiness. — That to secure these rights, Governments are instituted among Men, deriving their just powers from the consent of the governed, — That whenever any Form of Government becomes destructive of these ends, it is the Right of the People to alter or to abolish it, and to institute new Government, laying its foundation on such principles and organizing its powers in such form, as to them shall seem most likely to effect their Safety and Happiness."

THOMAS JEFFERSON, Declaration of Independence

THOMAS JEFFERSON, Declaration of Independence

Posted by

Belilove Company-Engineers

Thermal Solutions Designed for Aerospace

Advanced electric heating elements and thermal systems designed and manufactured for application-specific requirements in the harsh operating environment of outer space.

Experience, precision, and reliability. BCE.

http://heater.belilove.com | (510) 274-1990

Experience, precision, and reliability. BCE.

http://heater.belilove.com | (510) 274-1990

Posted by

Belilove Company-Engineers

9 Pin Vacuum Feedthrough

Nine pin circular feedthroughs (often called instrumentation feedthroughs) are commonly used for the transmission of low power electrical signals. They are designed for applications where typical Subminiature Type-D connections will not fit, or where there is little space. The circular geometry allows the installation of this feedthrough into very small vacuum flanges. They are often used in instrumentation applications such as semiconductor processing, electron microscopy, and a variety of analyzers.

Nine Berrylium-Copper alloy contacts, Gold plated per ASTM B488-01, are sealed and electrically insulated in a 304 stainless steel shell using the latest in ceramic bonding technology. Multiple contact configurations are available.

Specifications:

Nine Berrylium-Copper alloy contacts, Gold plated per ASTM B488-01, are sealed and electrically insulated in a 304 stainless steel shell using the latest in ceramic bonding technology. Multiple contact configurations are available.

Specifications:

- Leak Rate: 2X10 - 10 CC/Sec HE At One Atmosphere

- Laser Welded Assembly

- Hermetic Ceramic Seal for Contacts

- Temperature Rating: -65°C To 300°C

- Voltage: 750 AC RMS

- Current: 7 Amps

- Compact, Fits Easily into Complex Assemblies

- Adapts to Different Signals

- Mating UHV Connectors and Cables Available

Rapid Infrared Heating Reduces Energy Use, Improves Material Properties in Aluminum Forging

|

| Batch-type infrared (IR) furnace. |

The preheating of metal billets prior to hot forging as an opportunity for significant energy savings in the U.S. forging industry. Aluminum billet preheating is traditionally slow, costly, and energy intensive. Rapid infrared heating offers a faster, cheaper, and less-energy-intensive alternative to the gas-fired convection ovens that traditionally preheat forgings to above 800°F.

In a Department of Energy sponsored project, a scaled up a laboratory based, batch-type infrared (IR) furnace (see image) to create an optimized, hybrid, continuous IR furnace for industrial forging.

Demonstration of this IR furnace reduced preheating times for aluminum forgings from 1-6 hours to 14-18 minutes. The infrared pretreatment was 75% more energy efficient than conventional ovens, and the system proved robust under industrial conditions. The IR furnace demonstrated a downtime of less than 5% over three years of use in preheating billets.

Custom Electric Heating Elements

BCE designs and manufactures custom engineered heating solutions for analytical instrumentation, semiconductor, photovoltaic (solar), medical equipment, plastics processing, foodservice equipment, packaging, aerospace and many other industries.

Visit http://heater.belilove.com or call (510) 274-1990.

Visit http://heater.belilove.com or call (510) 274-1990.

Posted by

Belilove Company-Engineers

Need a Custom Design Electric Heating Element? Call Your Local Heating Element Sales Rep

|

| Your local heating element sales rep is your asset. |

Custom heating element design is best completed and accomplished through the proper application of the right resources. The local heating element sales engineer is an access point to high level technical knowledge and assistance that can be easily tapped and brought to bear on your successful task or project completion.

Local heater and control distributors and representatives provide services that will help you save time and money, with a greater chance of achieving a better outcome for the entire project.

Local heater and control distributors and representatives provide services that will help you save time and money, with a greater chance of achieving a better outcome for the entire project.

Consider these points regarding what the heating element sale rep brings to your project:

Develop a professional, mutually beneficial relationship with a heating element sales rep. Their success is tied to your success and they are eager to help you.

|

| Example of custom heating element (ceramic airflow heater) |

- Product Knowledge: The heating element sales rep will be current on product offerings, proper application, and capabilities. They also have information regarding what products may be obsolete in the near future. This is an information source at a level not generally accessible to the public via the Internet.

- Application Experience: As a project engineer, you may be treading on fresh ground regarding some aspects of your current assignment. There can be real benefit in connecting to a source who has decades of designing electrical heating elements.

- Access: Through a heating element sales rep, you may be able to establish a connection to “behind the scenes” manufacturer contacts who will champion your project internally. The rep knows people, makes it his/her business to know the people that can provide answers, and can act as your projects ambassador with the manufacturer.

Develop a professional, mutually beneficial relationship with a heating element sales rep. Their success is tied to your success and they are eager to help you.

Posted by

Belilove Company-Engineers

Swaged vs. Standard Cartridge Heater Design and Heater Life

Cartridge heaters provide localized heat to restricted work areas requiring close thermal control. Dies, platens and a variety of other types of processing equipment are efficiently heated. Closely controlled work temperatures up to 1400° F (760° C) are obtained by a combination of heater location and proper wattage output.

The most common cause of cartridge heater failure is an improper fit in the hole into which it is inserted. If the heater is surrounded by air, an excellent thermal insulator, it cannot dissipate it's heat into the part with optimum efficiency. The result is much higher temperatures on the Nichrome wire and failure. The goal to longer life with cartridge heaters is to accommodate the tightest fit practical for a given application.

Heater Life

Cartridge heater life is determined by how efficiently the heat generated in the resistance wire can be conducted away from the wire and into the part being heated. The efficiency of heat transfer is generally controlled by three factors:

- Resistance wire watt density

- Density of insulating material around the wire

- Fit of the heater into the heated part

There are two basic designs of cartridge heaters - swaged and standard. Although both type heaters look identical, the internal construction is very different.

Standard Cartridge Heater Design

|

| Standard Cartridge Heater Design |

Nichrome wire heating coils are inserted in holes formed in ceramic tubes. Pure magnesium oxide filler is vibrated into the holes housing the heating coils to allow maximum heat transfer to the stainless steel sheath. The heater then has a Heliarc welded end cap inserted on the bottom of the heater and insulated leads are installed. The MGO powder is not compacted and heat transfer is a function of the grain-to-grain thermal conductivity to the heater sheath, and then into the heated part. Because of this, the heater wire watt densities must be kept in the low to medium range.

|

| Swaged Cartridge Heater Design |

Swaged Cartridge Heater Design

Swaged cartridge heaters wind Nichrome wire around a precision ceramic core and the carefully position the resistance wire and ceramic core uniformly inside the the heater sheath. Pure magnesium oxide (MgO) powder is then vibrated in and the heater is swaged to a specific diameter. Swaging is a process that mechanically forces the heater through a confining die to reduce its diameter and thus compact the powdered MgO to rock-like consistency for greater thermal conductivity. This compressed MGO transfers the heat from the resistance wire much more efficiently. The improved heat transfer allows for higher wire watt densities allowing swaged cartridge heaters to operate at higher temperatures.Cartridge Heater Fit

In summary, if you want the longest life cartridge heater, choose a swaged heater and make sure you provide a machined, close tolerance fit between the outside diameter of the heater and the inside diameter of the hole.

Epoxy Feedthroughs A Better Option Than Glass-to-Metal for Under 200 Deg. C.

|

| Multi-conductor Flanged Epoxy Feedthrough (BCE) |

Failures due to contamination, dust, or leaks can be devastatingly costly, in both money and time.

Historically, glass-to-metal (GTM) hermetic seals have been used, but their limited size, shape, pin options, and shielding limitations have frustrated designers. A more accommodating and cost effective feedthrough solution was badly needed.

Enter epoxy potted feedthroughs. While GTM has a distinct advantage in very high temperature applications, in low-to-medium temperature applications newer epoxy resins are quickly gaining ground. Ideally suited for use where continuous temperatures stay under 200 deg. C , the versatility and cost of epoxy feedthroughs make them a clearly better choice. Additionally, in many cases epoxy feedthroughs can be prototyped and small quantities can be provided much more quickly.

Ultimately, epoxy vacuum feedthrough’s greatest advantage is their design versatility and option flexibility. Flanges, threaded connections, circuit board mounts, 120 volt receptacles, thermocouples, pneumatic tubes, Sub D connectors, and fiber optic cables are all examples of options that are easily accommodated. No longer does a designer have to conform their design to a standard glass-to-metal specification. Epoxy vacuum feedthroughs give designers the freedom to have a feedthrough that exactly meets their needs.

Why Cartridge Heaters Fail

By understanding the most common reasons cartridge heaters fail, users can take preventative steps in their applications to achieve optimum heater life and lower equipment ownership costs.

Improper Fit

The most common cause of cartridge heater failure is an improper fit in the hole into which it is inserted. If the heater cannot dissipate the heat being generated and produced by contact with the sheath, the temperature inside the heater will continue to rise until the heater fails.

Moisture and/or Impurities

The MGO used in cartridge heaters is hydroscopic. Every time power to electric heaters is eliminated, an internal vacuum occurs which draws in air from the surrounding area. If moisture or impurities (oil, gas, etc.) are present, they can be drawn in to the heater, and cause a short circuit resulting in a heater failure.

Watt Density is Too High

If the watts/square inch is excessive, the heater will not be able to dissipate the heat and the heater will fail.

Incorrect Voltage Applied

The wattage of any electric heater varies as the square of the voltage. If a 120 Volt heater is powered on 240 Volts, the wattage will be 4 times greater than that for the same 120 Volt heater. Under normal conditions, this may result in heater failure.

Frequent Temperature Cycling

Rapid cycling of heaters from very low to very high temperatures shortens their life considerably.

Improper Fit

The most common cause of cartridge heater failure is an improper fit in the hole into which it is inserted. If the heater cannot dissipate the heat being generated and produced by contact with the sheath, the temperature inside the heater will continue to rise until the heater fails.

Moisture and/or Impurities

The MGO used in cartridge heaters is hydroscopic. Every time power to electric heaters is eliminated, an internal vacuum occurs which draws in air from the surrounding area. If moisture or impurities (oil, gas, etc.) are present, they can be drawn in to the heater, and cause a short circuit resulting in a heater failure.

Watt Density is Too High

If the watts/square inch is excessive, the heater will not be able to dissipate the heat and the heater will fail.

Incorrect Voltage Applied

The wattage of any electric heater varies as the square of the voltage. If a 120 Volt heater is powered on 240 Volts, the wattage will be 4 times greater than that for the same 120 Volt heater. Under normal conditions, this may result in heater failure.

Frequent Temperature Cycling

Rapid cycling of heaters from very low to very high temperatures shortens their life considerably.

About BCE

BCE is a recognized leader in manufacturing and applying resistance heating elements in many industries, including medical, analytical, packaging, process, food equipment, and aerospace. BCE's extensive standard and custom product lines include:

- Cartridge heaters

- Immersion heaters - ideally suited for heating various liquids

- Air process heaters - for providing hot air and gas up to 1,400 degrees

- Stainless steel strip and thin strip heaters in various sizes

- Self-contained one-piece assembly coil and rope heaters

- Tubular and finned tubular heaters - specially built to resist impact, vibration corrosion and temperature extremes

- Band heaters for a multitude of applications

- Ceramic and crankcase heaters

For more information, visit http://heater.belilove.com or call (510) 274-1990.

Subscribe to:

Posts (Atom)